Benefits of Using ErectaStep’s Solutions Over Scaffolding

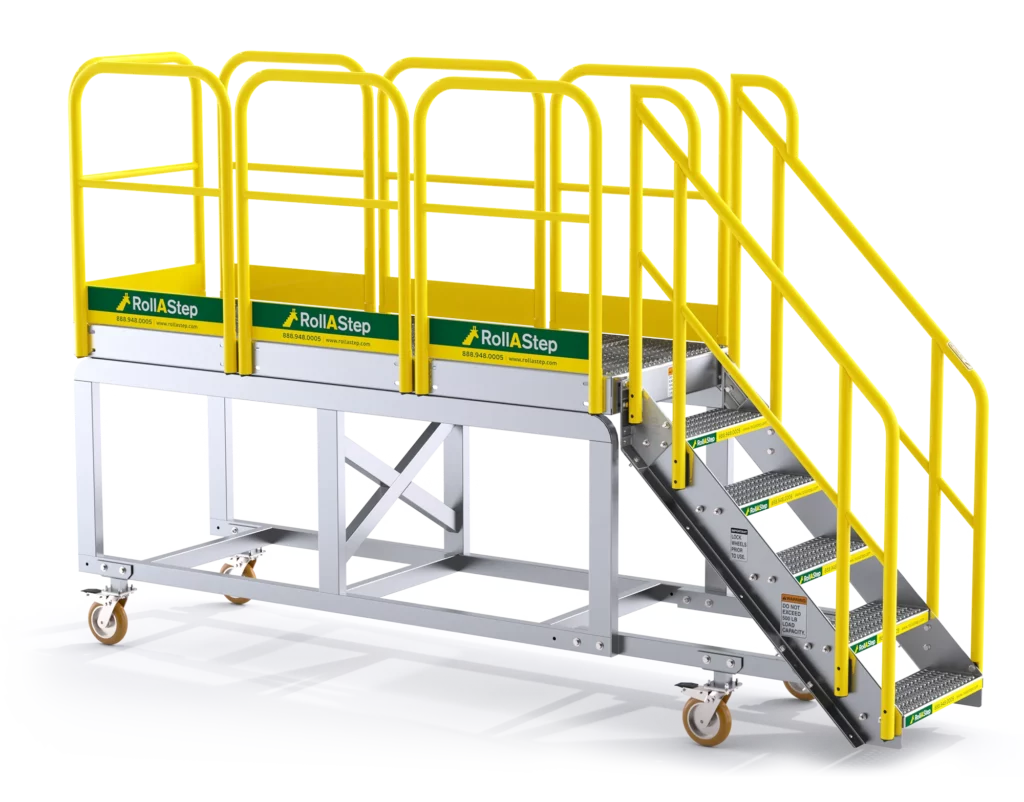

Traditional scaffolding presents many challenges and risks. ErectaStep & RollaStep products offer a superior alternative with modular, OSHA-compliant platforms.

Scaffolding Rental vs. Semi-Permanent Access Platforms

Renting or leasing metal scaffolding for semi-permanent or long-term applications has numerous disadvantages, including significant safety risks if not installed correctly. Regular inspections and re-certifications are necessary and costly fines if not performed on time. ErectaStep and RollaStep provide a long-term alternative to traditional scaffolding systems. ErectaStep’s patented, bolt-together design employs five modular components to create unlimited stair and access configurations, pre-engineered to meet or exceed OSHA standards. This drastically reduces the typical design and installation process from weeks to mere days, without the need for costly engineering.

Compliance Expert

A friendly expert is ready to discuss your project.

Tom Reeves

Your friendly stair expert

Better ROI

Traditional scaffolding involves ongoing rental fees, maintenance, and inspection costs. ErectaStep, on the other hand, is a one-time purchase with minimal ongoing costs, providing a better long-term return on investment.

Installation and Flexibility

Installing traditional scaffolding requires skilled labor and significant time. ErectaStep’s modular design allows for quick assembly and reconfiguration by less specialized labor, offering superior flexibility and speed.

Durability and Maintenance

Scaffolding is prone to wear and tear, necessitating regular maintenance. ErectaStep, constructed from durable materials like marine-grade aluminum, ensures longevity and minimal maintenance.

Safety and Compliance

Scaffolding poses a high risk of accidents and requires constant compliance checks. ErectaStep platforms are built to meet OSHA standards, providing a consistently safe working environment without the need for frequent inspections.

Project Profile

Chemical Facility Replaces Scaffolding with ROI in 18 months.

ErectaStep replaces scaffolding at Arizona nitrogen facility saving $38,000 annually.

Project Profile

ErectaStep Replaces Temporary Scaffolding at Refinery

ErectaStep installation at a petrochemical refinery, replacing expensive temporary scaffolding with durable, permanent metal stairs, pays for itself in two years, saving $12,000 annually by replacing rental scaffolding.

Key Benefits

Return on Investment (ROI)

Comparing traditional scaffolding with ErectaStep modular platforms reveals significant long-term financial benefits for the latter. While traditional scaffolding might seem less expensive initially, costs quickly add up with rental fees, frequent inspections and certification, and the need for skilled labor for assembly and disassembly. In contrast, ErectaStep’s modular platforms eliminate recurring costs associated with scaffolding, providing significant long-term savings. Additionally, traditional scaffolding requires regular maintenance, incurring additional costs. ErectaStep systems, constructed from marine-grade aluminum, are designed for durability and long-term use, significantly reducing maintenance costs, without the need for repetitive costly re-certifications.

Safety

Compliance and safety are critical concerns with scaffolding. OSHA citations for scaffolding violations are frequent, highlighting the inherent risks and the need for rigorous inspections by competent persons. ErectaStep platforms, however, always meet OSHA standards without requiring frequent inspections, ensuring continuous compliance and safety. Traditional scaffolding can be unstable and risky, especially in adverse weather conditions. ErectaStep’s platforms provide a stable and secure working environment, reducing the risk of accidents and injuries. Several industries have successfully replaced scaffolding with ErectaStep solutions, resulting in improved safety records. For example, projects in the defense and heat exchanger maintenance industries have reported significant safety improvements using ErectaStep systems.

Productivity

The ease of installation and reconfiguration of ErectaStep platforms significantly boosts productivity. Traditional scaffolding requires skilled labor and is time-consuming to install. Additionally, weekly and sometimes daily inspections by competent persons

take time, causing personnel to wait around unproductively. This hidden cost adds up over the year. In contrast, ErectaStep’s modular design allows for quick and easy assembly by mechanical fitters, reducing downtime and labor costs. ErectaStep’s platforms can be easily reconfigured for various applications, enhancing operational flexibility. Many industries and plants have experienced productivity boosts by switching to ErectaStep solutions, showcasing the efficiency and versatility of modular platforms.

Sustainability

Traditional scaffolding often involves heavy materials with high environmental footprints. ErectaStep systems, made from recyclable aluminum, contribute to reduced environmental impact. Furthermore, ErectaStep platforms support green building initiatives by contributing to LEED credits through their sustainable manufacturing processes and recyclable materials.

| Issue | Traditional Scaffolding | Modular Platforms (both ErectaStep or RollaStep) |

|---|---|---|

| Install | Requires trained, competent, qualified scaffolding technician. | Is modular in design, bolted together, and easy to assemble, requiring Mechanical Fitters to install. |

| Permits | None | None |

| Pre-Use Inspection | Required | Not required |

| Minimum 7-day Inspection | Required | Is modular in design, bolted together, and easy to assemble, requiring Mechanical Fitters to install |

| OSHA Compliance | Can be either an operational expense or capital expense to suit client needs | YES, ALWAYS |

| Materials of Construction | Galvanized steel tube and timber • Heavy • Heavy to transport, environmental impact • Installation challenge | Marine Grade Aluminium • Corrosion resistant • Powder-coated Handrails. • Low environmental impact • This is an inherently non-emitting source of VOCs |

| Monthly Fees | Yes | No |

| Dismantle | Not required. Good working practice will often schedule an annual inspection. | Modular in design, bolts together and easy to disassemble by mechanical fitters. |

| Re-Purpose | It can be either an operational expense or a capital expense to suit client needs. | Is modular in design, bolted together, easy to disassemble, requiring Mechanical Fitters. |

| Productivity/Throughput | Scaffolding can be ergonomic, but it also requires lifting and carrying heavy materials, awkward postures, and repetitive motions. It is not the safest or most efficient way to do the job. | An OSHA modular solution, rigid, stable, and designed to combine Safety with Productivity. |

| Ergonomics | This solution aims to create safe, comfortable, and productive workspaces by bringing human abilities and limitations into the design of a workspace. | Depending upon the application, this can be anything from 120 days and out. There are outliers. |

| CAPEX or OPEX? | Requires trained, competent, qualified scaffolding technicians. | Depending upon the application, this can be anything from 120 days and out. There are outliers. |

| ROI | This should be carefully considered. Careful review of: • Project timeline • Supplier • Operator training • Maintenance/Inspection • Downtimes | Depending upon application, this can be anything from 120 days and out. There are outliers. |