Improving Worker Comfort and Productivity Distribution Center and Manufacturing

In the industrial environment, ergonomics goes beyond the comfort level; it becomes the foundation of workforce efficiency and safety. ErectaStep’s ergonomic platforms illustrate that the ergonomic design is integrated into daily operations, thus reducing injury risks and increasing productivity. This article looks into the critical role of ergonomic practices, emphasizing ErectaStep’s solutions that combine function and worker well-being-essential in today’s fast-paced industrial environment.

The Role of Ergonomics in Industrial Productivity.

Ergonomic practices are essential in minimizing workplace injuries and increasing productivity. Tulane University highlights that ergonomically designed workspaces prevent long-term health problems. Thus, absenteeism is reduced, and efficiency is increased. As per OSHA compliance, the implementation of ergonomic interventions can significantly reduce musculoskeletal disorders, which are the leading causes of workplace disability.

According to Dr. Alan Hedge, the professor at Cornell University, the use of ergonomic principles in industrial design is a must for the workers’ comfort and efficiency. It cuts down fatigue and boosts job satisfaction, which, in turn, leads to better performance and lower turnover rates.

The WHO highlights that about 1.71 billion people are living with musculoskeletal conditions that are the number one cause of disability in the world. Therefore, these conditions greatly restrict mobility and dexterity, which, in turn, results in early retirement from work and a decrease in participation in society. Ergonomic practices can reduce the impacts of physical and mental exhaustion by modifying workplaces to prevent the onset of musculoskeletal diseases.

Some Common Ergonomic Challenges Found in the Workplace

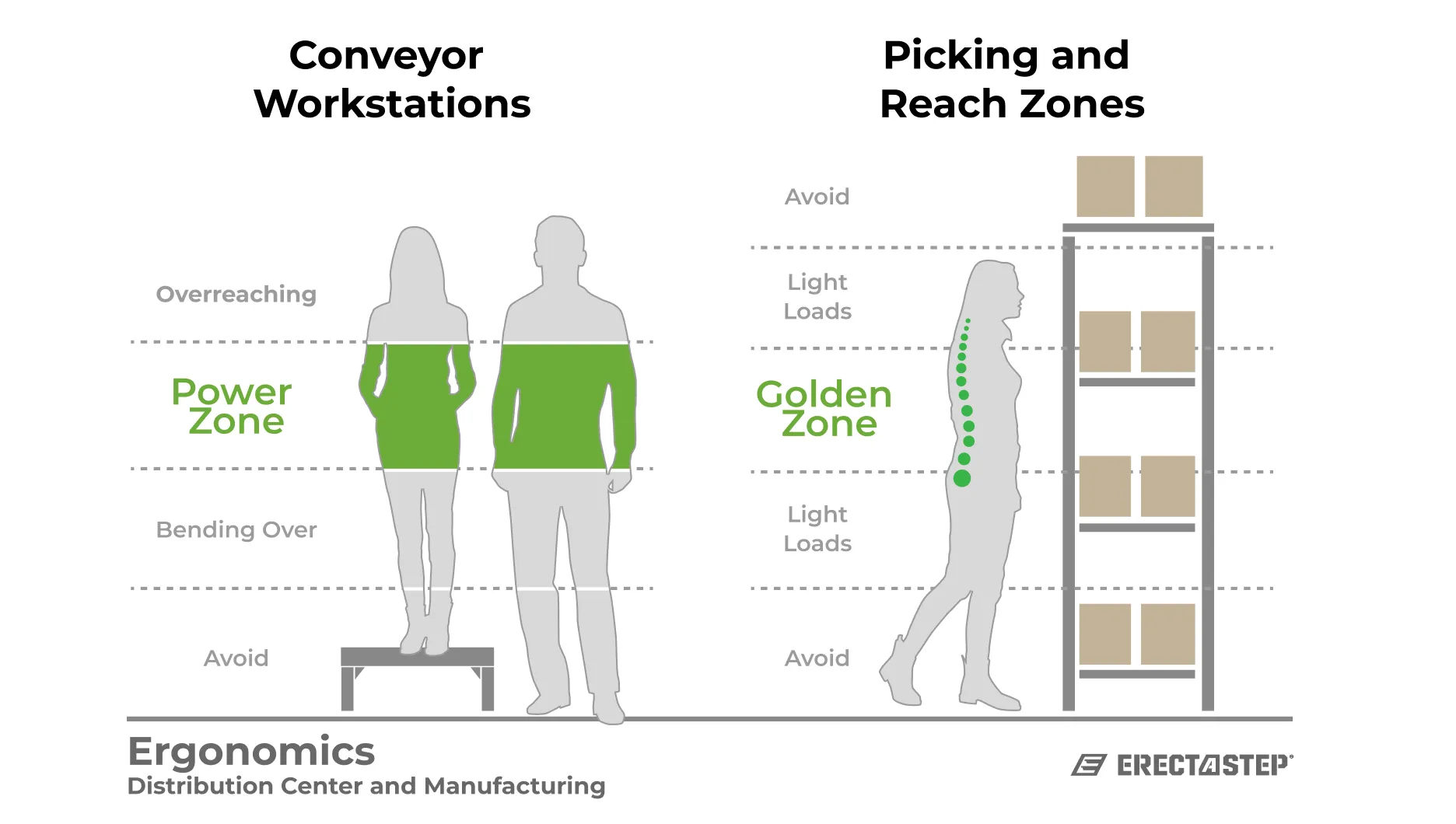

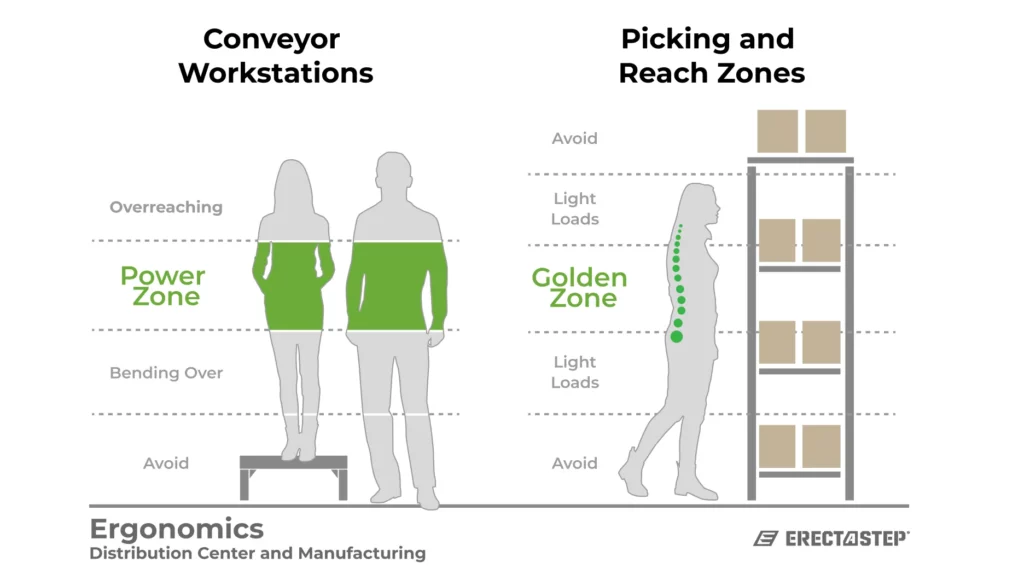

In industrial settings, the workplace is full of ergonomic challenges that lower productivity and endanger workers’ health. A typical problem is the misalignment between the design of workstations and the physical requirements of the tasks. Hence, the workers are always in the state of reaching, bending, or twisting.

The muscle and joint misalignment thus causes the strain of the muscles and joints, which increases the risk of injuries such as tendonitis or carpal tunnel syndrome. Besides, the usual static postures or repetitive motions in assembly line work can worsen these problems, leading to long-term discomfort and disability.

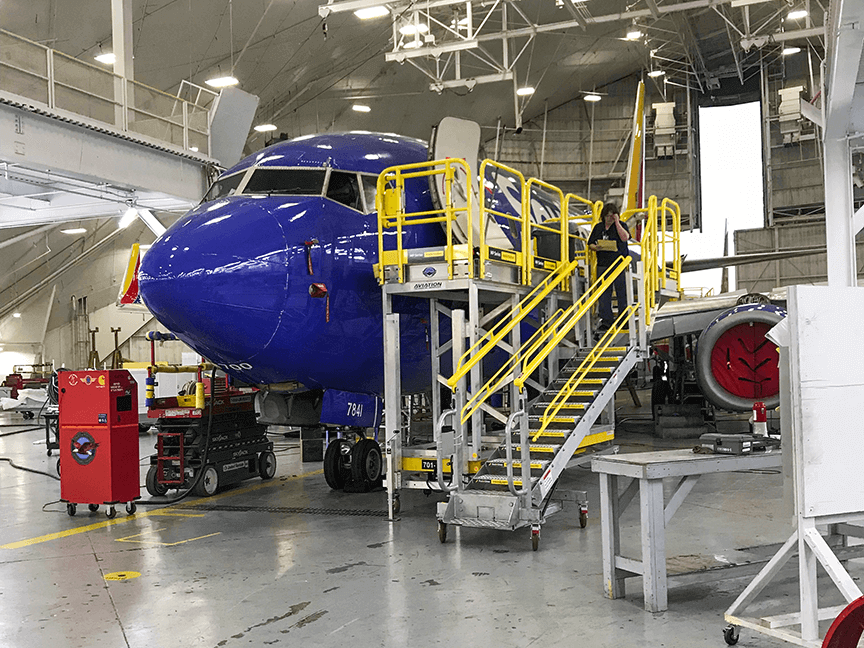

The ErectaStep adjustable work platforms solve these problems by offering adjustable heights and configurations that fit the proper work postures and significantly decrease physical stress. These prefabricated access platforms provide solutions that can be applied to different industrial activities; hence, workers can conduct their work in a safe and efficient way without endangering their health, making the work environment productive and safe.

ErectaStep’s Ergonomic Platform: Improving Industrial Workplaces

| Feature | ErectaStep’s Ergonomic Platform | Traditional Solutions |

|---|---|---|

| Adjustability | Fully adjustable heights and modular components | Fixed heights, limited adjustability |

| Material Durability | Powered coated industrial-grade aluminum | Paint surfaces require additional coats over time and metal can rust or corrode, especially with exterior applications |

| Ergonomic Design | Designed to support natural body mechanics and reduce strain | Often not tailored for ergonomics |

| Safety Compliance | OSHA compliant, ensuring safety | May not meet current safety standards |

| Ease of Installation | Modular design for quick assembly | Less impact on productivity can increase fatigue |

| Flexibility | Can be reconfigured for various tasks | Static design with no reconfiguration options |

| Impact on Productivity | Reduces fatigue and increases efficiency | Less impact on productivity, can increase fatigue |

| Material Benefits | Aluminum – Lightweight, sturdy & maintenance free | Often requires more maintenance and isn’t as durable |

Case Study: ErectaStep in Action

ErectaStep’s ergonomic conveyor platforms are used in a Sonoma winery, where custom installations have significantly improved the conveyor assembly line operations. Using these ergonomic access platforms, the winery solved the typical ergonomic problems. Thus, it enabled the workers to have a natural posture while doing intricate tasks like wine bottling. This adaptation resulted in the drop of the musculoskeletal complaints among employees who before were suffering from the discomfort caused by the prolonged standing and the awkward positioning.

The ergonomic enhancements made possible by ErectaStep not only raised the workers’ satisfaction but also increased productivity and made the work environment safer, thus showing the real benefits of individual ergonomic solutions.

Implementing Effective Ergonomic Practices

The ergonomic practices are the industrial organizations’ most important tools to boost the workers’ productivity and health. The key element of the successful implementation is the evaluation of the work processes, the detection of ergonomic risks, and the possibilities for improvement. ErectaStep’s ergonomic safety platforms are the best example of this approach because they provide the perfect, height-appropriate solutions to any workplace.

Investing in such ergonomic tools helps in immediate comfort and provides long-term benefits such as significant savings on healthcare costs and reduced turnover rates, increasing the overall ROI. The training of the staff on the importance of ergonomic practices and how to use ergonomic equipment correctly is equally important. Furthermore, constant review and change of these practices guarantee their continued efficiency as the operational demands change.

Conclusion

Adopting ergonomic solutions like ErectaStep’s ergonomic work platforms is the key for modern industrial environments, which are interested in increasing productivity and, at the same time, ensuring the safety of workers. The integration of ergonomic practices by companies is not only the compliance with the safety regulations but also the workforce’s health gets invested; thus, the operational success and employee satisfaction are sustained for a long time.

Sources

ErectaStep. (n.d.). Ergonomic Platform. Retrieved from

https://www.erectastep.com/products/industrial-stairs/ergonomic-platform/

ErectaStep. (n.d.). Ergonomic Bottling Conveyor Platform. Retrieved from

https://www.erectastep.com/installations/ergonomic-bottling-conveyor-platform/

ErectaStep. (n.d.). Bottling Conveyor Platform at a Winery in Sonoma. Retrieved from https://www.erectastep.com/installations/bottling-conveyor-platform-at-a-winery-in-sonoma/

Tulane University School of Public Health and Tropical Medicine. (n.d.). Workplace Ergonomics & Safety. Retrieved from

https://publichealth.tulane.edu/blog/workplace-ergonomics-safety/

Occupational Safety and Health Administration. (n.d.). Ergonomics. Retrieved from https://www.osha.gov/ergonomics

World Health Organization. (n.d.). Musculoskeletal conditions. Retrieved from https://www.who.int/news-room/fact-sheets/detail/musculoskeletal-conditions

University of California, San Diego. (n.d.). Ergonomics Awareness. Retrieved from

https://blink.ucsd.edu/safety/occupational/ergonomics/awareness.html#Food-service-workers

Dalmec North America. (n.d.). Why Proper Ergonomics Are Essential in Manufacturing Workplaces. Retrieved from

https://www.dalmec-na.com/blog/why-proper-ergonomics-are-essential-in-manufacturing-workplaces/

SafetyCulture. (n.d.). Ergonomics Training. Retrieved from

https://safetyculture.com/topics/ergonomics-safety/ergonomics-training/