Defined by the Occupational Safety and Health Administration (OSHA) as “one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees,” a competent person is authorized to take prompt corrective measures to eliminate workplace dangers. Their responsibilities extend to scaffolding safety.

Only a “competent person” can inspect scaffolds, as defined by OSHA (OSHA standard §1926.450(b)). This individual must be able to identify and predict hazards in the work environment and be authorized to take corrective action. Regular inspections by a competent person ensure scaffold safety and compliance with OSHA standards, preventing accidents and maintaining a secure job site for all workers.

How to Properly Inspect a Scaffold

The first step in scaffold inspection is confirming that its construction adheres to the design and engineering requirements of the project. A thorough inspection process should ensure that:

- The scaffold is securely in place and stable

- The scaffold is level and plumb

- The scaffold is erected within a safe distance from power lines

- The scaffold can support the weight of its load rating

- All screw jacks are appropriately adjusted

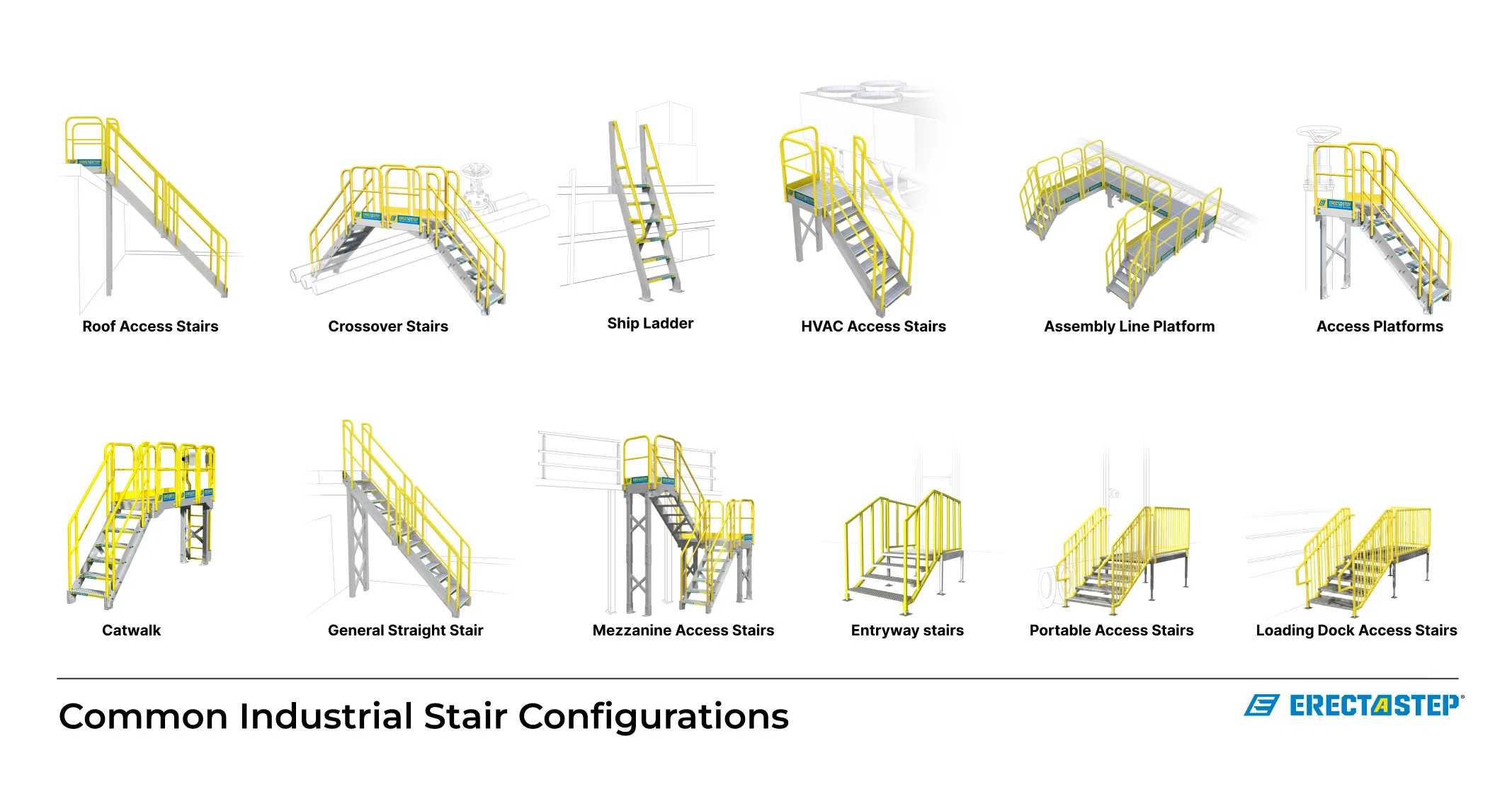

- Stairs and ladders are secure and of acceptable width and condition

- All openings and gaps in the scaffold are small enough to not present opportunities for falls

- An appropriate amount of guardrails and toe boards are in place

- The base plates are placed on an appropriate surface

- The sills are the correct size and properly installed

- The bracing components are securely attached

- The decking and planks are of adequate performance rating and grade

- Any ties, anchorages, outriggers, and guy systems meet height-to-base ratio requirements

- The scaffold shows no visible defects

These inspections should be conducted by a fully trained, competent person before the start of each new shift, after any occurrence that could affect its structural integrity, and at any time when a scaffold is erected, dismantled, moved, or altered in any way. Failure to do so could result in accidental injury or death.

OSHA estimates that 65 percent of construction workers perform tasks on scaffolds each year, so there is bound to be an accident at some point. In addition to falls, scaffolding-related accidents often involve structural instability, overloading, falling objects, and electrocution. To ensure the safest possible job site, your crew must be appropriately trained in scaffold safety.

Training Your Scaffold Workers

By law, anyone who works on and around scaffolding must be trained in compliance with Title 29 of OSHA’s “Safety Standards for Scaffolds Used in the Construction Industry.” The standards were revised in 1996 to address protective measures and training for construction workers who work on scaffolds. Such revisions that were not previously covered by the OSHA scaffold standards included:

- Falling object protection

- Ladders

- Weather conditions

- Aerial lifts

- Stilts

The revised standards established scaffold load-carrying capacities, which stated each scaffold and component must support, without failure, its own weight and at least four times the maximum intended load. Revisions also required personal fall protection systems such as guardrails and harnesses to be made available to protect all employees working at a 10-foot height above a lower level.

Fall Protection Tips for Scaffold Safety

Scaffold safety is important to protect your workers. All scaffolding workers should practice and implement the following scaffold safety tips:

- Securely anchor personal fall protection systems to prevent a fall exceeding 6 feet

- Inspect personal fall protection systems for wear and tear damage before each use

- Wear hardhats whenever working on, beneath, or near a scaffold

- Wear non-slip work boots when on a scaffold

- Always be mindful of others working above, below, and alongside a scaffold

- Do not leave unsecured items on the scaffold when not in use

- Limit the use of stilts unless the guardrails are of appropriate height

- Never use unauthorized or unsecured objects to extend a scaffold’s reach

- Always adhere to all grab line system, guardrail, and fall protection requirements

- Keep in mind the scaffold’s maximum intended load

- Never climb a scaffold that is slick, muddy, icy, damaged, or not fully assembled

- Do not use a scaffold in inclement weather

While each construction site is different, the above scaffold safety tips can provide a proper foundation of jobsite safety awareness that can be useful for any crew.