Whether you call it handrails, guardrails, or just plain ‘railings,’ these are all designed to prevent people from falling off from elevated work areas or from moving into restricted entry work zones. Falls ensue whenever employees move or walk, losing their balance away from their center of gravity, resulting in severe physical injury or trauma in one or more body parts. Companies and government entities set up railings to safeguard employees to conform with the Occupational Safety and Health Administration (OSHA) guidelines. In addition, establishments should formally declare that all their structures abide by the American Disabilities Act (ADA) guidelines for publicly accessible business facilities.

Why are Guardrails and Handrails Important?

Handrails provide a way for people to hold onto and keep balance when ascending or descending stairs. Aside from stairs, guardrails and handrails are vital because they provide a way for people to hold onto or grab on to maintain balance when in balconies, mezzanines, decks, rooftops, work platforms, or any elevated walkway to prevent fall injuries right before they happen.

Get the full scoop: What are the differences between handrails vs. guardrails?

What is alarming is that falls, trips, and slips are entirely avoidable incidents, but business and building owners sometimes overlook installing these railings. In the latest Bureau of Labor Statistics (BLS) data in 2019, falls, trips, and slips rank as the second cause of fatal occupational injuries after transport-related accidents. In addition, falls, trips and slips caused 880 worker deaths and 244,000 more employees needing days off from work because of hospitalization/recovery period connected with these job-related injuries in the US.

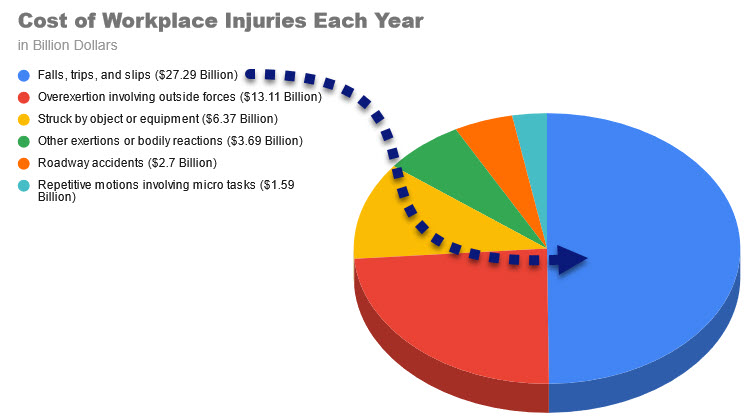

If you think that installing these handrails and guardrails is expensive, think about the costs of worker compensation you have to shell out per incident: $20,000 each! According to the 2019 Liberty Mutual Workplace Safety Index, the employers have to pay for falls, trips, and slips, summed up to $27.29 billion each year. For these costly worker compensation reasons, you better have these compliant railings in place before facing any penalties from OSHA violations and worker lawsuits.

Liberty Mutual just released their 2021 Safety Index for the Top 10 Causes of Disabling Injuries for Workers. Although their index accounts ‘Handling Objects’ on the #1 spot. Let’s not forget, they relegated falls, trips, and slips to #2, #3, and #7 — accounting for 33.1% of all injuries that SHOULD be on the top spot!   |

What are the Different Types of Handrails?

Two main types of handrails exist:

- Handrails that go along a staircase

- Handrails that provide support for people who need to stand or sit in one spot

The first type is more flexible because it can be installed on either side of the stairs as required but may not always be the best option if there is no wall on one side. On the other hand, this style will work well if you want to make your metal stairs safer by preventing falls. It’s also easier to install than the second type.

The second type supports people who need assistance when sitting or standing still, like those you see in “accessible toilet stalls” for differently-abled people. Ensure these rails should only be used where they will not get in someone’s way – such as if you need to get by regularly while someone is sitting in their wheelchair, for example. They can be installed alongside the wall or away from it, and they come with different finishes to match your building design or structures.

Both of these handrail types are beneficial because they offer support and safety for people with different needs.

What is the Handrail Height Code?

Everyone is caught between a rock and a hard place about the handrail code. Even countries and states have additional code requirements like Canada’s National Building Code (NBC) or California’s CAL-OSHA. These ‘codes’ often refer to several safety recommendations from agencies (OSHA & IBC) to public access assistance provision for people with different needs (Americans With Disabilities Act Standards for Accessible Design [ADASAD]). It is crucial that a building or business owner be aware of these codes, or a more convenient option would be to hire a local contractor who needs to be well-versed in these national and local building codes.

In practice, handrails should remain continuous on both sides and around the landing (save for entrances). In addition, the ADA has set handrail height standards: a minimum of 34 inches and 38 inches at maximum when used at the top to the bottom of stairs, ramps, or inclines to provide additional support when going up or down steps/incline surfaces, except in places where extensions could obstruct pedestrian flow along walkway routes.

For safety reasons in workplaces where fall hazards are common, the OSHA has set handrail height to be a minimum of 42 inches, while the IBC has established these guidelines:

- a minimum of 42 inches for guardrails

- a minimum of 34 inches for handrails

Get the full scoop:

Below is a helpful table to help you navigate around the most common guardrail and handrail height codes:

| IRC | IBC | ADASAD | OSHA | NBC (Canada) | ||||

|---|---|---|---|---|---|---|---|---|

| Residential | Commercial | General | Where children are primary users (recommended, not required) | General | Stair Rail System | Residential | Commercial | |

| Handrail Height | 34″ to 38″ | 34″ to 38″ | 28″ with a minimum of 9″ clearance between the child and adult handrail | 30″ to 38″ | 36″ to 38″ — may also serve as guard | 34″ and 42″ | 34″ and 42″ | |

| Guard Height | 36″ minimum | 42″ minimum | not specified | 42″ — plus or minus 3″ | 36 to 38″ | 36″ minimum | 42″ minimum | |

When are Handrails Required?

Handrails are required under the following circumstances:

- When a worker must use stairs, ramps, or steps to access another building level, all areas with no alternative route that will provide safe passage without using stairs should have handrails, including doorways and landings at the top and bottom of staircases.

- If any area on a level, including hallways and corridors, contains one or more steps with the span of four inches (100 mm) or more within 36 inches (910 mm) horizontally to the ground.

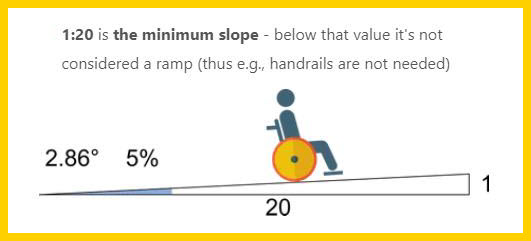

- The design of ramps can allow for the installation without handrails. Handrails are only required in an employee work area if it’s a walking surface with running slopes less than 1:20 in height that doesn’t need to have rails in place.

The final authority on whether or not to install handrails comes down to your local building codes.

Do I Need a Handrail for Three Steps?

As a general rule, no. OSHA recommends that you only want one for stairs with a height of three feet or more or four or more risers (steps). Now, is it illegal to have no handrails? Generally no, but you should consult a professional familiar with local building codes to be safe than sorry.

How to Install Handrails?

An installation of a safety handrail is necessary to ensure comfort and secure those who are both able and differently-abled. If permanently fixed to the wall, these railings should not be detachable. Setting handrails as fixed and non-detachable enough to withstand a minimum of 200 pounds of force firmly will ensure that it does not come loose from the wall if a person pulls on it, leading them to threats of bodily injuries.

When installing new handrails, they must have at least one intermediate horizontal section about two-thirds of the way up for resting places or areas where the railing is too low.

Safety inspectors measure the height of a handrail from where it makes contact with the floor to a point at least 34 inches above that, and it must not exceed 38 inches in total height. Thus, a good handrail height for most adults would be 35-38″.

For workplace safety concerns, industrial facilities and commercial establishments should not attempt DIY solutions on handrail installation. Besides, most handrail and stair retailers often offer installation services to assure their products are correctly installed.

Fitting handrail brackets for rails attached to a wall and newel posts that support the entire rail system are the most crucial parts of the installation process. Ensuring these handrail parts are securely attached by professionals is necessary to avoid accidents resulting from improperly installed stair or guardrail system components.

How far apart should two railings be placed?

There is no maximum clearance between two handrails because it will depend on the width of the stairs. However, OSHA set the minimum width for stair treads:

The minimum clearance of a handrail between any other object is 2.25 inches (5.7 cm).

Ultimately, all questions you might have about handrail and guardrail safety are discussed on OSHA Laws and Regulations page. Routine inspections enforce these standards. So, if you do not want penalties, better head over to the OSHA guidelines and familiarize yourself with it or hire professionals to do these assessments for you.

These guidelines are put in place to avoid a situation involving imminent danger, loss of life or limb, or worker complaints. Current employees or their representatives may submit a written complaint to OSHA requesting an inspection of their workplace if they feel a severe hazard threatens their well-being or their employer is not abiding by OSHA regulations.