The Challenge—Create an OSHA-compliant custom conveyor crossover ladder in an area with a low ceiling. The client didn’t want heavy steel or on-site welding and required all parts to be powder-coated with a custom color theme.

ErectaStep, a brand known for top-quality industrial stairs, work platforms, and ladders, recently designed and built a custom conveyor crossover ladder system for one of the world’s most innovative electric automobile manufacturer’s factories. The manufacturer needed a unique industrial solution to crossover a conveyor but required it to meet unique specifications while providing OSHA compliance and aiding productivity. They needed a quality solution with a high aesthetic value, one that would be entirely powder-coated and match their organization’s colors. The restricted environment in which the conveyor crossover ladder system was installed had a lowered ceiling and other challenges. ErectaStep was called upon to create a solution that would meet the needs of the environment and the manufacturer and maintain OSHA compliance. Because of the lowered ceiling, a standard 6-inch thick platform would cut it too close for most workers to properly do their jobs safely. ErectaStep could provide a cost-effective solution while meeting all requirements and needs.

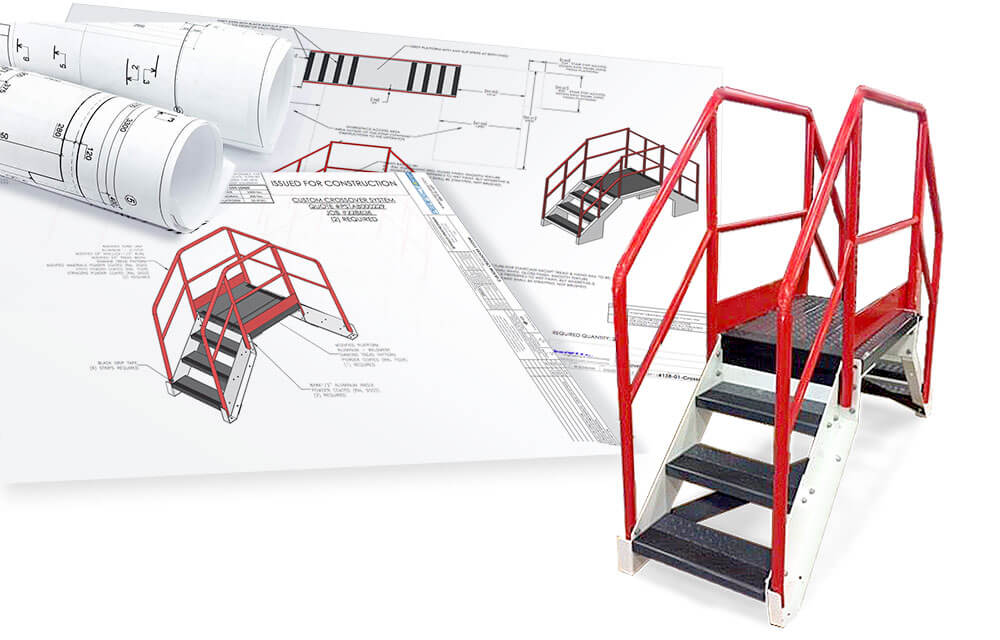

Custom Conveyor Crossovers in the plant, being QC’d and getting ready to ship

An additional restriction was that they wanted lightweight materials and not heavy steel. Additionally, it had to be assembled on-site without welding, and ErectaStep’s modular lightweight aluminum components and bolt-together design became the perfect solution! We eliminated the need for custom fabrication and the weeks of estimates, drawings, edits and installation time typical to custom fabrication solutions. The ErectaStep system gave them the ability to have pre-fabricated components created in advance to prevent any factory downtime during assembly and installation.

Along with some customized components, ErectaStep’s lightweight aluminum components, and modular, bolt-together design was the perfect solution!

ErectaStep provided a solution that utilized platforms 3 inches less than the standard size, but were as sturdy as the 6-inch variety and stayed within compliance. Along with the custom platform height, the automobile manufacturer also wanted color-specific powder coating of the entire crossover ladder, platform, and handrails. We also added non-slip tape on the stair treads and leading edges based on the organization’s preference. Single handrail sections were used to span across the platform and stairs to ensure safety and stability on the reduced work platform height.