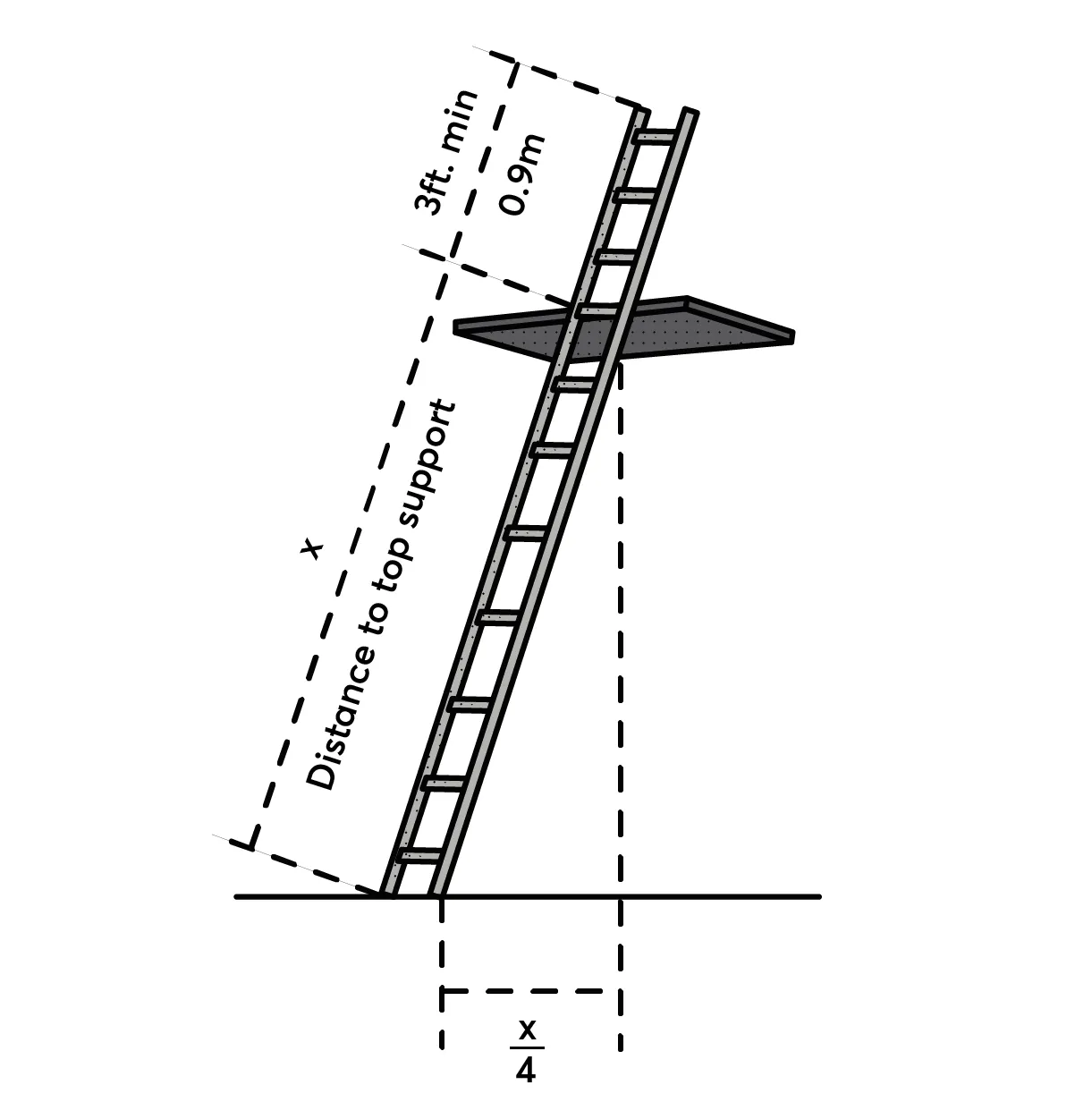

The working length of a non-self-supporting ladder is the distance from the base to the top bearing point, indicating its usable reach. This measurement is crucial for ensuring the ladder is used safely and effectively in various settings.

Understanding the working length is important for selecting the appropriate ladder for various tasks, ensuring that it can reach the necessary height while maintaining stability and safety.

Key Benefits:

- Safety: Ensures the ladder can reach the necessary height without compromising stability.

- Smartness: Helps in choosing the appropriate ladder size for specific tasks, reducing setup time.

- Compliance: Adheres to OSHA requirements for ladder safety and usage.

Applications:

- Providing safe access to elevated areas for construction workers.

- Facilitates maintenance, repairs, and routine checks at heights.

- Useful for tasks such as roof access, gutter cleaning, and painting.

Material Considerations:

- Aluminum Ladders: Lightweight and resistant to corrosion, ideal for outdoor use.

- Fiberglass Ladders: Electrically non-conductive, suitable for tasks near electrical sources.

- Wooden Ladders: Traditional option, though less commonly used in industrial settings due to weight and maintenance considerations.

The working length is the distance from the base to the top bearing point, indicating the ladder’s usable reach.

OSHA Compliance for Working Length

OSHA guidelines ensure that ladders are used safely by defining the working length and other important dimensions. Key OSHA requirements include:

- Design: The ladder must be long enough to provide a stable and safe working length.

- Inspection: Regular inspections are required to ensure the ladder maintains its structural integrity and proper working length.

- Usage: Proper training for workers on how to use ladders safely and effectively.

Ensuring these guidelines will help prevent accidents and maintain workplace safety.