Pultrusion is a manufacturing process used to create reinforced plastic shapes by pulling fibers through a resin bath and then through a heated die. This technique results in strong, durable materials ideal for constructing various products, including ladders.

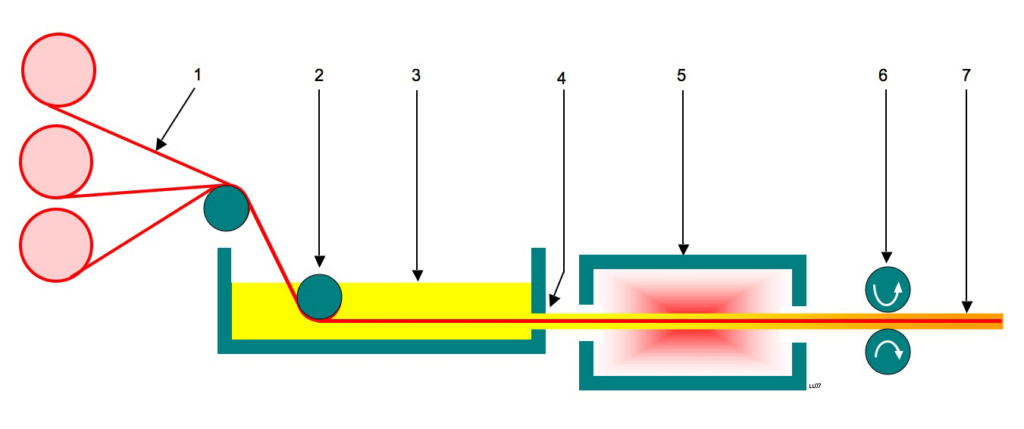

Diagram of the pultrusion process.

- Continuous roll of reinforced fibers/woven fiber mat

- Tension roller

- Resin impregnator

- Resin soaked fiber

- Die and heat source

- Pull mechanism

- Finished hardened fiber reinforced polymer

Key Benefits:

- Improved Strength: Offers superior durability and long-lasting performance.

- Lightweight: Easier to handle and transport due to reduced weight.

- Corrosion Resistance: Pultruded materials resist corrosion well, making them ideal for outdoor and industrial use.

Applications:

- Used to create lightweight yet sturdy ladders that can withstand significant loads and harsh conditions.

- Ideal for producing high-strength components in construction and industrial applications.

OSHA Compliance for Pultruded Ladders:

Key OSHA guidelines for Pultruded Ladders:

- Load Capacity: Ensure that pultruded ladders meet or exceed OSHA’s load capacity requirements for the intended use.

- Material Standards: Follow OSHA guidelines for the materials used in ladder construction to ensure safety and durability.

- Regular Inspections: Conduct regular inspections of pultruded ladders to maintain compliance and ensure ongoing safety.