Ship ladder rooftop installation

Categories: Ship & Fixed Ladders Commercial Ladder Platform Roof Access Rooftops

Ship ladder rooftop installation

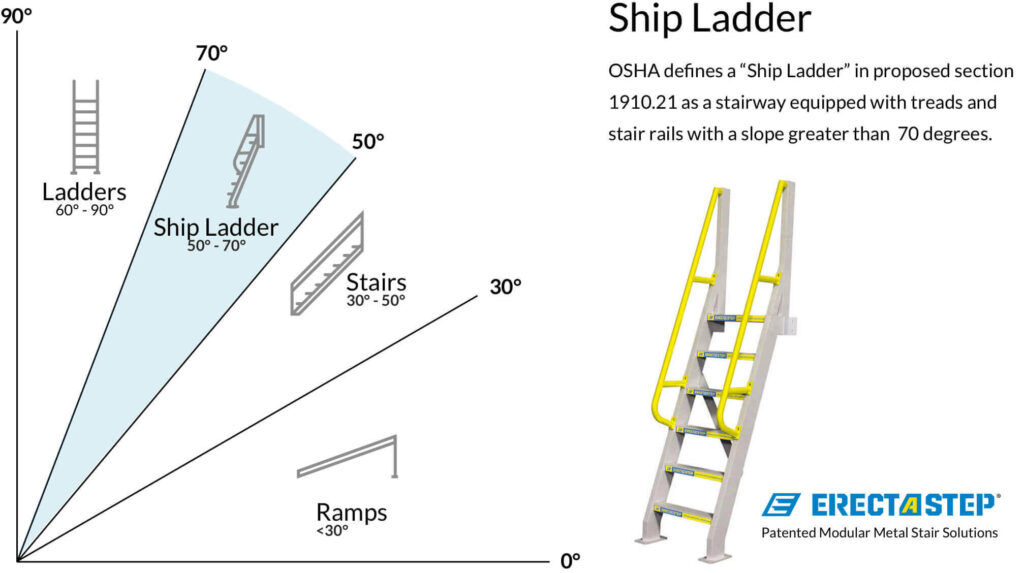

An ongoing misconception suggests that a ship ladder is meant only for ships or marine vessels. A ship ladder is a type of stairway originally used aboard ships. Shipbuilders were forced to create steps with extremely steep slopes to compensate for ships' restricted deck space. These staircases were dubbed "ship stairs" or "ships ladders."

OSHA defines a "ship ladder" as a ladder or stair with treads and handrails with a slope of more than 70 degrees in proposed section 1910.21. Although this does not imply that these stairs are solely used on ships. Rather, the word refers to steps or ladders that have an incline of between 50 and 70 degrees, and its uses are in places where regular stair length runs are not realistic. Accessibility for maintenance and production in a safe manner is an absolute necessity in virtually every type of industrial setting.

OSHA introduced Section 1910.28(b)(9)(i) in 2018 to require any fixed access ladder that reaches higher than 24 feet above a lower level to have a personal fall arrest or ladder safety device installed. Before implementing this new regulation, it was believed that ladder cages and back guards offered enough fall protection to employees who were ascending/descending fixed ladders. However, repeated injuries and fatalities demonstrated that this was not the case.

A ship ladder offered a better choice to meet OSHA and IBC standards to avoid additional personal fall arrest systems and cages. By decreasing the incline between 50 to 70 degrees (as opposed to the 90 degrees in most access ladders), a ship ladder is built for optimal safety, comfort, and support.

In addition to the decreased incline, ship ladders also offer a variety of other safety features. Handrails are positioned on both sides of the ladder rungs, and the platform at the top is larger than average to provide extra stability. Some designs also come with rest platforms every few rungs, giving employees respite from the efforts of climbing at an incline.

In the photo above, the roof has a parapet wall on edge. The ship ladder provided access to that wall encircling the view of equipment on the rooftop.

Rooftop ladder inclines can be a major cause of workplace falls. The ladder angle can make it difficult to maintain your balance, and the lack of a handrail can make it easy to lose your footing. In addition, rooftop ladders are often located near air vents or other openings, creating drafts that make it difficult to stay on the ladder. Workers working on a rooftop ladder need to be reminded to take extra precautions to avoid falling. They need to wear sturdy shoes with good traction and use a safety harness if one is available. Most importantly, never work on a rooftop ladder alone when dealing with 90-degree inclines and dangerous heights. Having a second person nearby can help prevent falls and assist if a worker loses his or her footing.

When selecting, go for a ship ladder crafted from heavy-duty aluminum that is lightweight, resistant to corrosion, and does not require any maintenance. Aluminum ladders are a popular choice for both commercial and residential applications. They are lightweight yet strong, making them easy to transport and position. In addition, aluminum ladders are non-conductive, so they can be safely used near electrical equipment. Rooftop ladders in custom configurations are also available, which can be a handy option when working on multi-story buildings or other high places. Overall, aluminum ladders offer a variety of advantages that make them a good choice for multiple industrial applications.