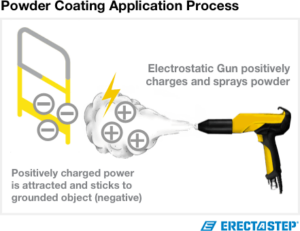

Powder coating is the application of a dry polymer finish onto a surface that has been chemically or mechanically cleaned, removing dirt, oils, old finishes, and oxidation.

Painting is using liquid solvent to spray pigment and binder to a solid surface. The drying process is the solvent evaporating leaving just the pigment and binding agent.

| Powder Coating | Paint | |

|---|---|---|

| PROS |

|

|

| CONS |

|

|

Powder coating was introduced in the 1960’s and it’s no wonder it’s become an extremely popular form of dry finishing, given all its redeeming attributes. It now represents over 15% of the total industrial finishing market and is used on a full range of products. Powder coating allows for a high-quality, durable finish, is aesthetically pleasing and is even much more environmentally friendly than it’s traditional paint counterpart. Powder coatings are available in almost any color and texture, and can withstand harsh environments making it the safer option for dry finishing.

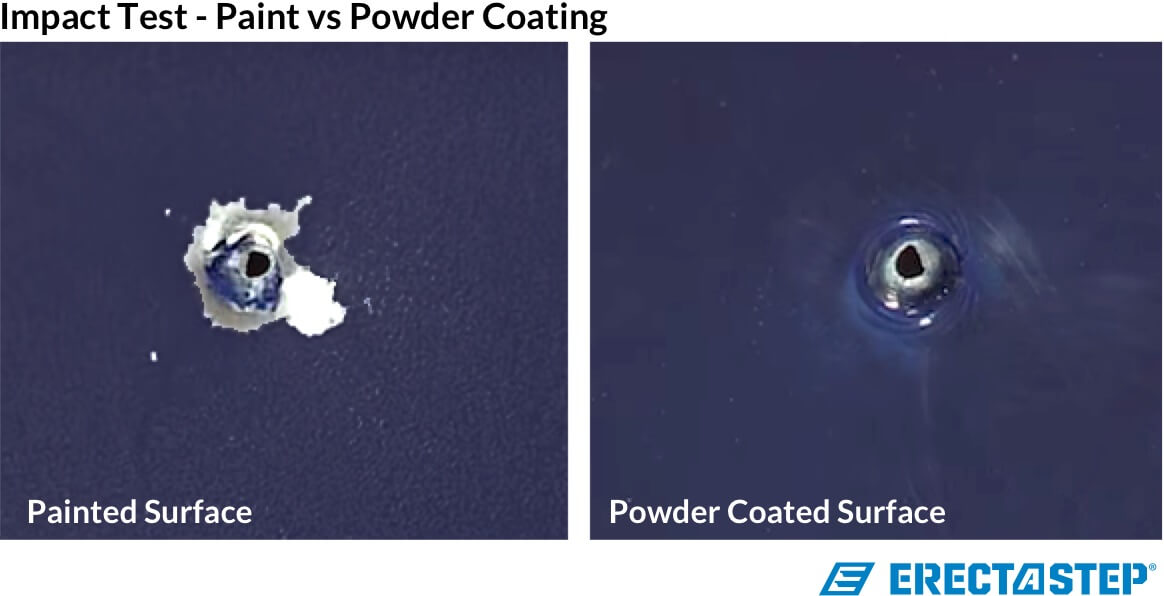

Durability is an important feature in any product manufacturing, especially when it comes to industrial equipment. With powder coating, equipment is much more resistant to scratching, peeling or chipping. The thick finish of a powder coat also allows for a greater protection of the equipment. Whether a product is undergoing a chemical test or is in a harsh environment, the durability of the powder coat will serve as a protective for the equipment.

Powder Coated Handrails

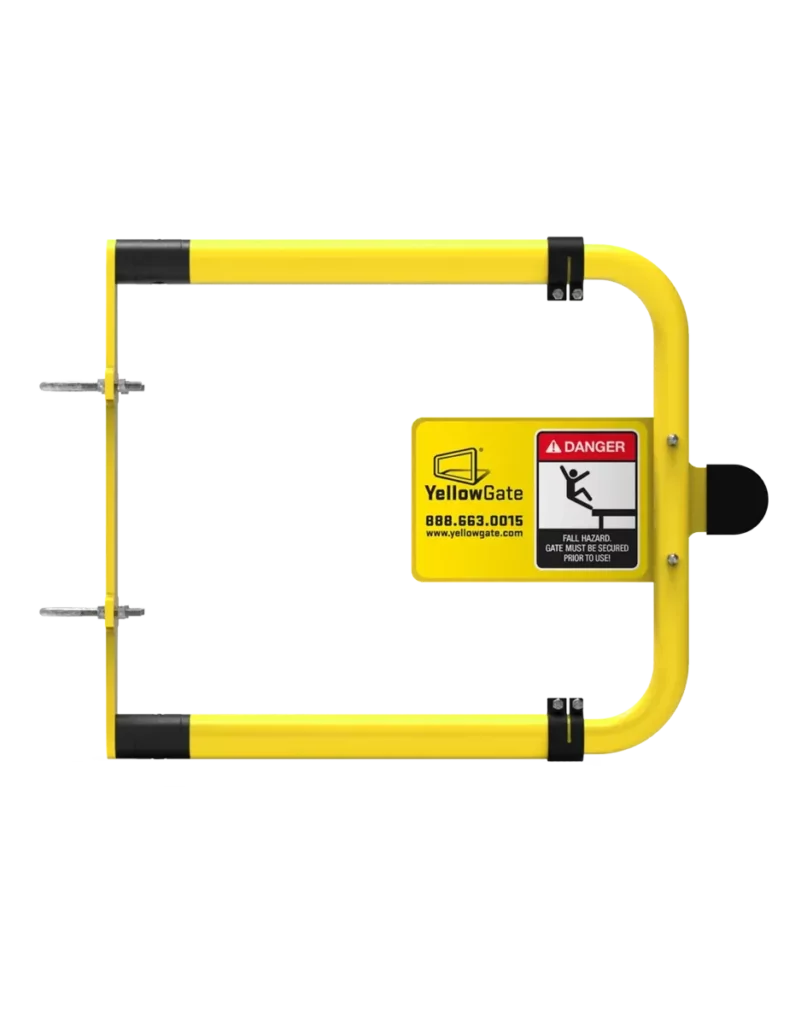

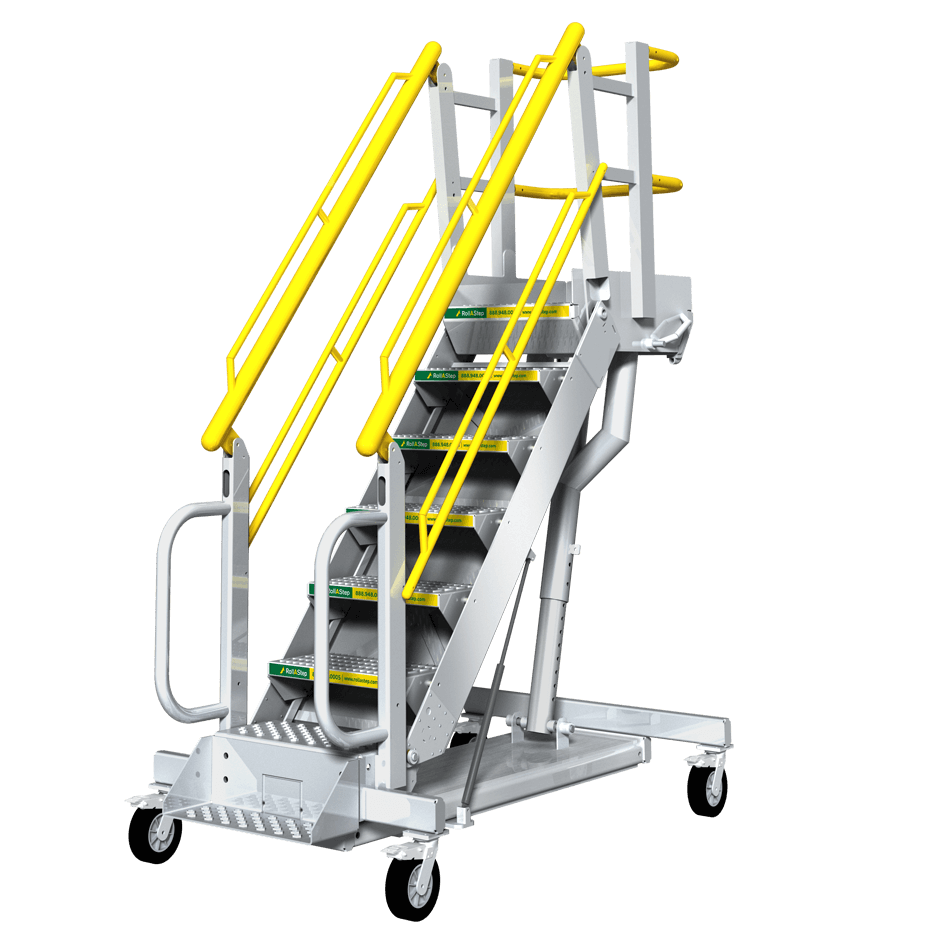

ErectaStep aluminum handrails and metal stairs are built with heavy-duty aluminum with a design load of 200 pounds in any direction. The ANSI safety yellow powder coating resists moisture, corrosive chemicals, scratches, chipping, corrosion, fading and wear. The thick round pipe has an outer diameter of nearly 2″, which helps with gripping and ensures the industrial railing endures years and years of wear and tear.

Aesthetics are important for any business as well. We all want our products to perform well, but making them look good is important too. Again, powder coating outperforms traditional paint in this case as well. While traditional paint often runs and drips, powder coating does not, therefore resulting in a more uniform look once the dry finish process has been completed.

In this day and age companies are becoming increasingly aware of how their business practices affect the environment, and when it comes to what’s better for the environment, powder coating far exceeds the safety of liquid paint. One of the biggest factors is that there are no volatile organic compounds (VOC’s) released into the atmosphere and nothing needs disposal at the end of each batch. In terms of safety to the technicians and engineers using these products, traditional paint compounds, such as acetone, have been known to cause respiratory problems to painting technicians. So ultimately powder coating is safer for both the environment and your employees!

Traditional painting still has its place in the dry finishing world. Powder coating, while ultimately cheaper with a high volume of product, has some initial start up costs that may not be feasible for a company with a smaller volume of product. In some instances traditional paint is a fast and practical way of dry finishing, but ultimately if you’re a company with a high volume of product, powder coating will be the best process to use based on it’s durability, aesthetics and overall safety for both the environment and the company employees.

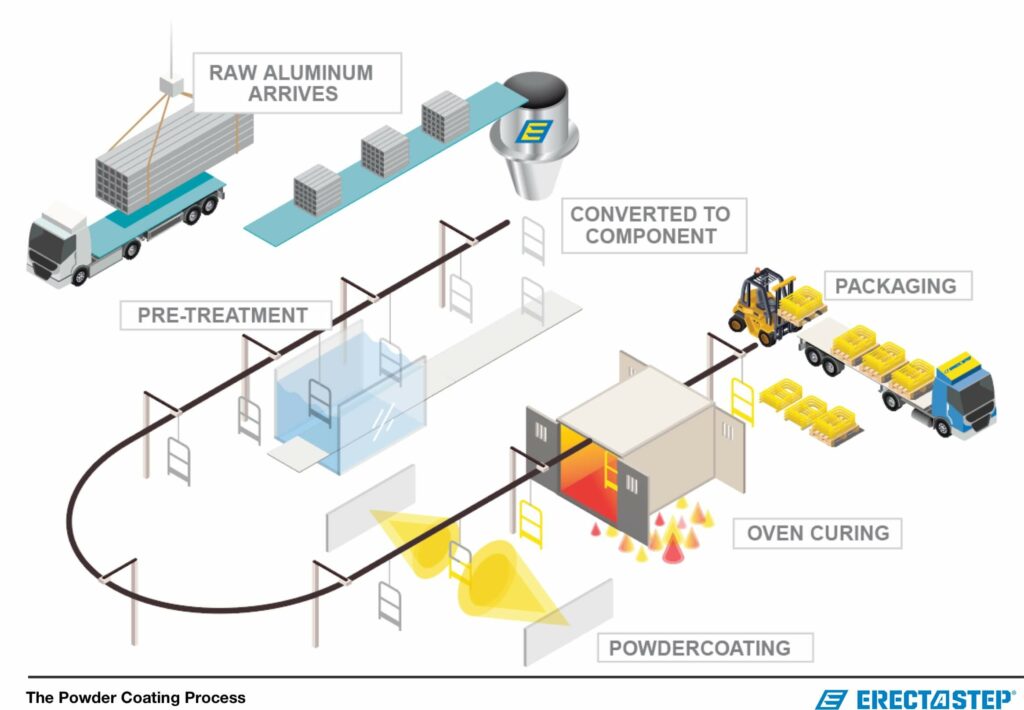

A powdered mixture of finely ground pigment and polymeric resin is sprayed onto an electrostatically charged metal surface. When heated in a curing oven, the resin particles melt and fuse into a strong and pliable bonded coating. The result is a high-quality coating with an attractive finish and excellent durability.

Our line of powder coated products

References:

http://www.powdercoating.org/page/WhatIsPC

https://www.thomasnet.com/articles/custom-manufacturing-fabricating/powder-coating-pro-con