Fall Protection/Prevention Expert and SafeRack CEO, Rob Honeycutt is featured in the March/April 2016 issue of Industrial Distribution

Safety is an issue for everyone in industrial and warehouse environments. That’s why so many distributors offer a safety product line, if not make it their core offering. This month, ID is focusing on two prominent safety categories:

Eye protection isn’t what it used to be. Safety glasses of yesteryear are bulky, heavy, and largely designed as one-size-fits all for cost savings. But as OSHA citations and fines are on the rise for the first time in 25 years, and the cap penalty OSHA can impose has nearly doubled, employers are realizing that spending a little more up front on eye protection products tends to pay off in the long run.

“The relationship between improved design and compliance is simple: workers requiring eye protection are more likely to put on – and keep on – safety glasses that look good and provide long-term comfort,” says Katie Mielcarek, Marketing Manager for Gateway Safety. “This trend is relevant for employers who want to both avoid OSHA citations and, more importantly, keep their employees safe.”

Mielcarek says that one of the biggest areas of improvement in eye protection is in regards to the temple area – behind the eyes. Poor temple designs can put too much pressure on this area, pinch the back of the head, or cause glasses to fall off in hot, sweaty conditions.

“Workers that don’t find their eye protection comfortable will frequently put their safety glasses on top of their heads, or remove them entirely,” Mielcarek says. “By focusing on specialized temple features that improve comfort, manufacturers can produce products that workers will want to wear, which encourages employers to buy, and distributor businesses to grow.”

Like with any industrial product, technology is constantly changing to fit the needs of PPE users. When it comes to eye protection, products that answer the need for both protection and comfort will improve compliance. A pair of safety glasses can be the best in the industry at protecting the eyes, but can still be a poor product if employees tend not to wear them because of comfort issues.

“Safety eyewear products that offer better fit and comfort – with emphasis on unique temple design – will improve compliance,” Mielcarek says. “Distributors should be looking for manufacturing partners who are listening to end user needs and finding innovative ways to produce better safety eyewear for today’s workers.”

At the STAFDA convention, Roberts spoke about the evolution of safety products, using fall protection as an example. When Roberts started his career in 1979, a fall protection unit was usually just a safety belt with a single D-ring and a six-foot nylon rope lanyard with snap hooks on both ends. It sold for about $50 to the end user.

“Today, standard fall protection is a full body harness with a retractable shock-absorbing landyard system that sells for about $300,” Roberts said.

Obviously, the cost of fall protection products have risen significantly over the last 37 years, but so have their ability to ensure users come home safely.

With 7,402 citations last year, fall protection was OSHA’s top safety violation of 2015 for a fifth-year running. Trips, slips, and falls are among the most common causes of serious work-related injuries and deaths.

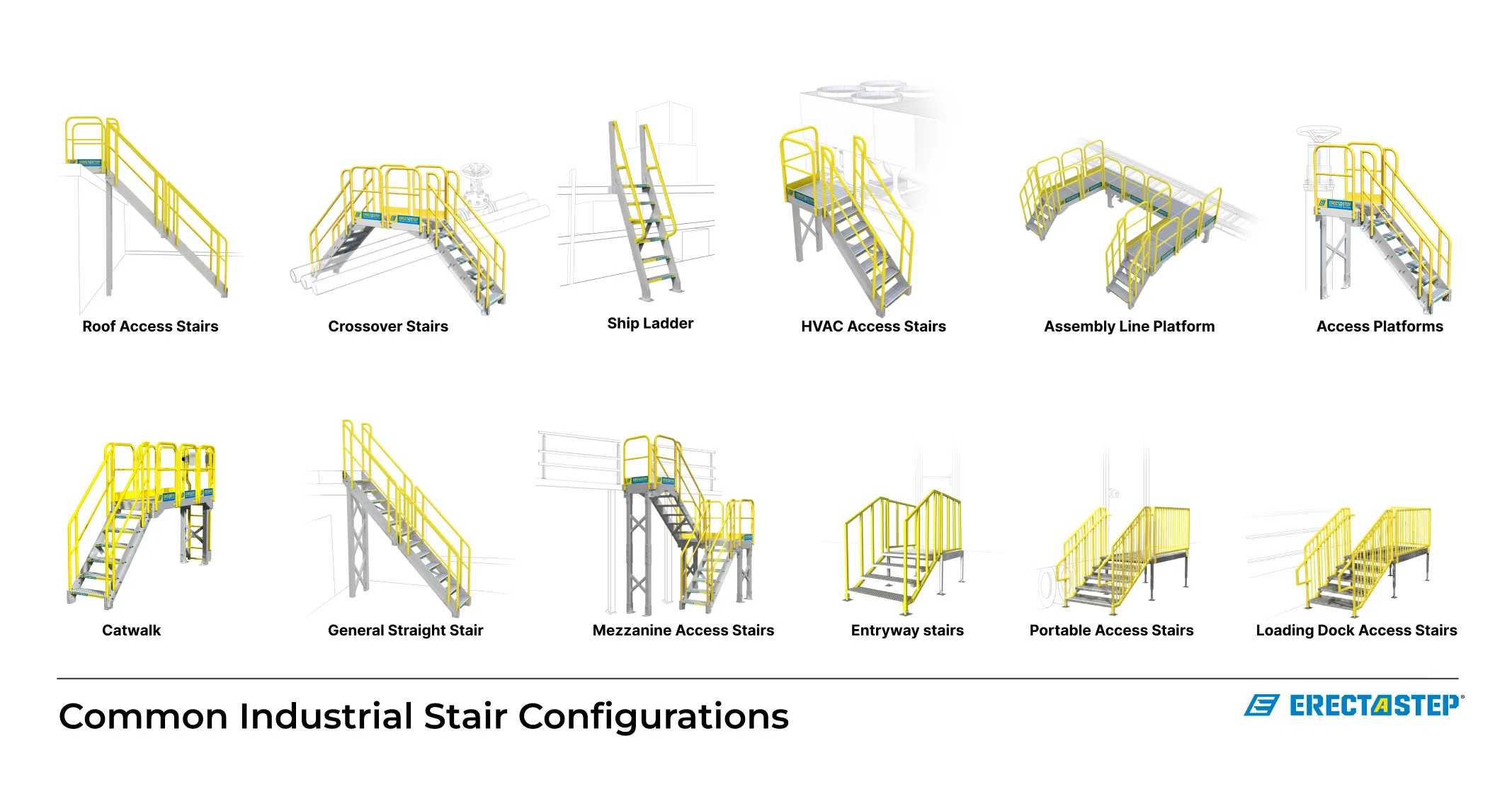

“Slips, trips and falls are preventable, and it’s vital that employers put effective workplace strategies in place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in walls and floors,” says Rob Honeycutt, co-founder of fall protection solutions provider SixAxis.

Today’s OSHA standards require that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry, and eight feet in longshoring operations. In addition, OSHA necessitates that fall protection be provided when working over dangerous equipment and machinery, regardless of the fall distance.

“OSHA’s four-foot rule has continued to generate platform, stair and handrail projects and many specialty fall protection products – like gangways for tank car and trucks – continue to grow,” Honeycutt says.