A distillery in Portland, Oregon had been using a ladder to access the top of their large distilling tanks. Recognizing the safety hazard presented for employees who needed access to the tanks, plant management decided to mitigate risk, providing a safer work environment for their staff by installing a more intelligent solution with ErectaStep.

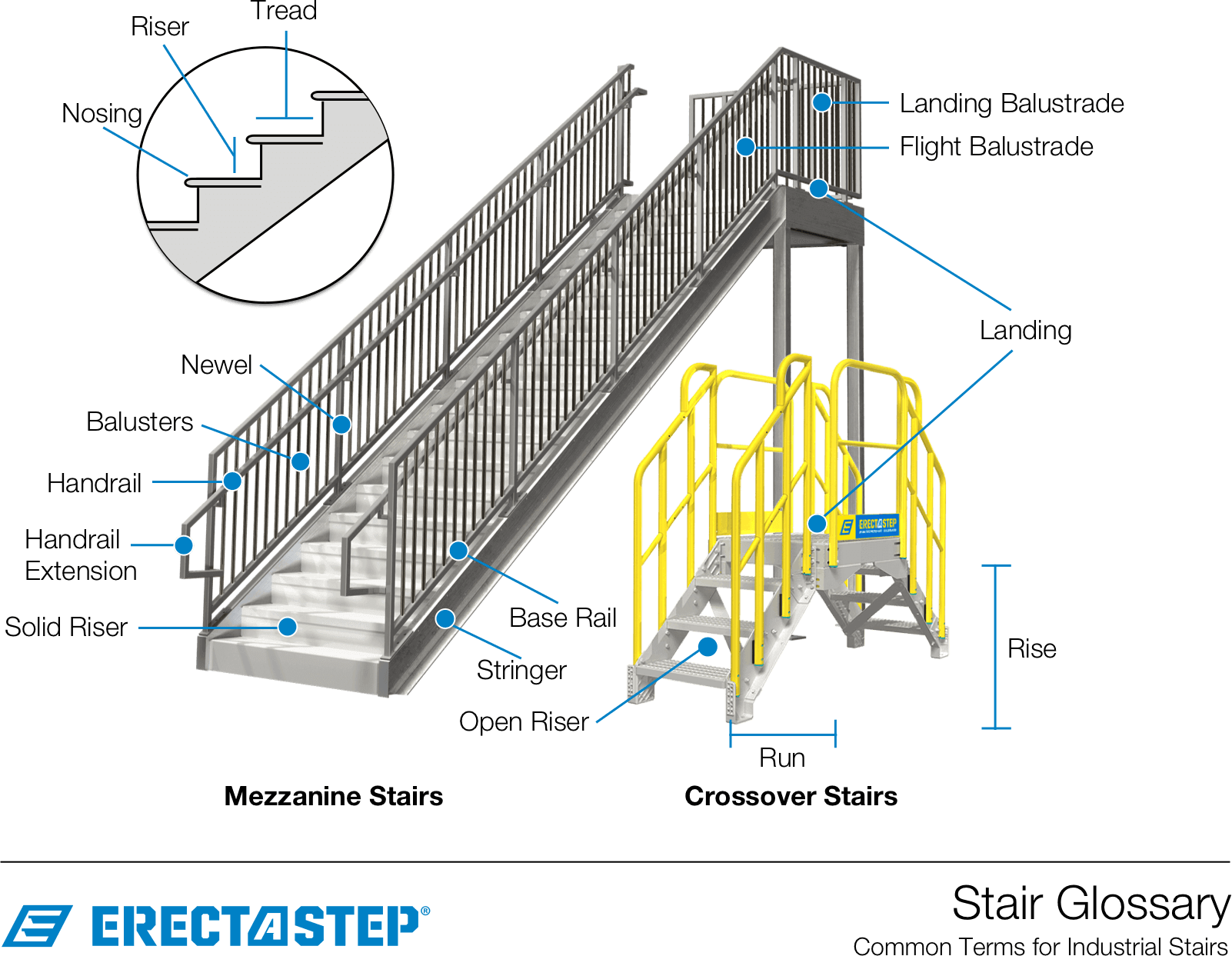

West Coast Territory Sales Manager Scott Johnson made a visit to the distillery and worked with the distillery team to come up with a safe alternative. It was determined that a crossover system would provide safety compliance as well as long-lasting protection from falls and injuries. The modular, pre-manufactured system allows employees access to the tanks without the risk of injury. The customer was quite happy with the proposed solution grateful that a costly customized solution wasn’t necessary. After installation of the safe, budget-friendly solution they immediately saw why ErectaStep was the appropriate choice.

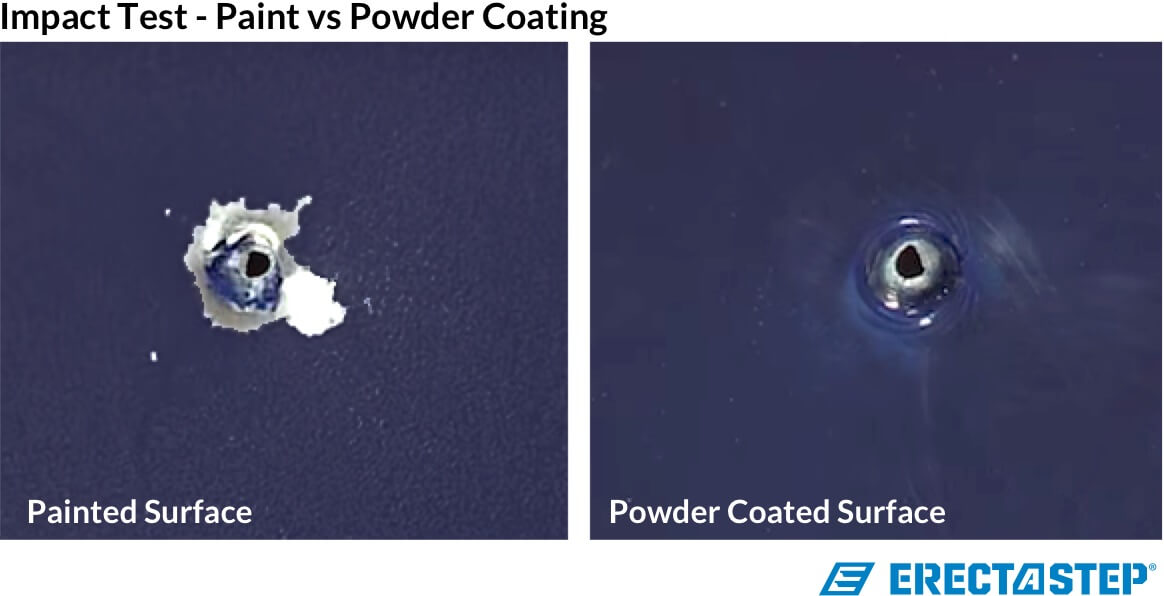

Pre-engineered and pre-manufactured ErectaStep stair kits are built using advanced laser-cutting technology and use durable powder coated handrails to ensure operator safety, as well as superior quality and durability. “The success of the project led to a productive ongoing client relationship, a true partnership, that has led to significant growth for the distillery,” explains Johnson.

“The company loved our solution so much that they are planning to purchase two additional C series ErectaStep crossovers as the business expands in 2019.”

Mutually beneficial relationships are what ErectaStep is all about. Our experience designing and building OSHA and IBC compliant metal stairs and access platforms spans two decades. Manufactured with precision and fully engineered for operator safety, we succeed when you succeed.