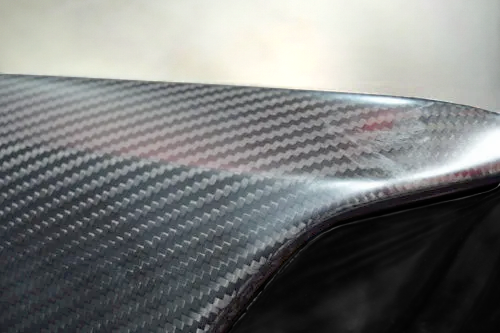

Reinforced plastic is a composite material made by embedding high-strength fillers, such as glass or carbon fibers, into a plastic matrix. This enhancement significantly increases the material’s strength, durability, and resistance to various environmental factors, making it ideal for demanding applications.

Key Benefits:

- Increased Strength: Provides superior strength and load-bearing capacity compared to standard plastics.

- Durability: Offers high resistance to impact, corrosion, and environmental wear, increasing the lifespan of the product.

- Lightweight: Reduces the overall weight of the ladder, making it easier to handle and transport.

Applications:

- Utilized to produce lightweight yet strong ladders that can withstand significant loads and resist impacts.

- Employed in various industrial components where high strength and durability are required.

- Used in structural elements where both strength and resistance to harsh conditions are crucial.

OSHA Compliance for Reinforced Plastic Ladders:

The Occupational Safety and Health Administration (OSHA) provides guidelines to ensure reinforced plastic ladders meet safety standards. Key points include:

- Load Capacity: Ensure that reinforced plastic ladders meet or exceed OSHA’s load-bearing requirements for safety.

- Material Standards: Follow OSHA guidelines for material strength and quality to maintain safety and performance.

- Regular Inspections: Conduct regular inspections to verify that the ladders remain in good condition and meet safety standards.