Imagine walking up stairs that appear to float in mid-air, defying gravity with each step. Cantilevered stairs have transformed modern architecture since the 1990s, creating stunning focal points that blend engineering precision with minimalist aesthetics. These floating staircases represent more than just a way to move between floors—they’re architectural statements that enhance space, light, and the overall feel of contemporary homes.

Whether you’re an architect planning a luxury residence or a homeowner dreaming of a striking renovation, understanding cantilevered stairs is essential. This comprehensive guide will walk you through everything from structural engineering principles to material choices, installation requirements, and cost considerations. You’ll discover how these seemingly impossible structures work and why they’ve become synonymous with modern elegance.

What Are Cantilevered Stairs?

Cantilevered stairs, commonly known as floating stairs or floating staircases, are architectural marvels where each tread extends from a supporting wall without any visible supports underneath. Unlike traditional staircases that rely on visible stringers, posts, or risers for support, cantilever stairs create the illusion that each step is suspended in space, literally floating in the air.

The key to this floating effect lies in the hidden structural supports anchored deep within reinforced walls. Each tread connects to a robust steel framework concealed behind the wall surface, creating a seamless and airy feel that allows light to flow freely through the space. This design approach eliminates the visual bulk associated with conventional staircases, making rooms appear larger and more open.

What sets cantilevered staircases apart from traditional stairs isn’t just their appearance—it’s their fundamental engineering approach. While conventional stairs distribute weight through multiple visible support points, cantilever staircases transfer all loads back to a single, heavily reinforced wall structure. This creates unique structural requirements but delivers unmatched visual impact.

The popularity of floating steps surged in modern architecture as designers sought ways to create more open, light-filled spaces. These stairs have become a hallmark of contemporary design, frequently featured in luxury homes, galleries, and commercial spaces where the staircase itself becomes a piece of functional art.

How Cantilevered Stairs Work: Structural Engineering

The engineering behind cantilevered stairs involves sophisticated load distribution principles that make the impossible appear effortless. Each tread functions as a cantilever beam, anchored at one end to the wall and extending freely into space. The hidden steel stringer systems, typically fabricated from heavy-duty steel beams or custom-designed support brackets, are embedded directly into reinforced concrete or heavily reinforced masonry walls.

For residential applications, cantilevered steps typically support loads of up to 250kg per tread, though this can vary based on local building codes and specific design requirements. The treads can safely extend up to 1500mm from the supporting wall, though most residential installations range between 800-1200mm for optimal proportion and structural efficiency.

The engineering calculations for these structures are complex, requiring careful analysis of bending moments, shear forces, and deflection limits. Each tread must resist not only vertical loads from users but also horizontal forces and potential twisting moments. The wall connection points experience concentrated loads that must be distributed effectively throughout the structure.

Advanced finite element analysis (FEA) is often employed to model the stress distribution and ensure safe load transfer. The design must account for both dead loads (the weight of the stair materials) and live loads (occupants and furniture), with appropriate safety factors built into every calculation.

Support Wall Requirements

The foundation of any successful cantilever stair installation is a properly engineered supporting wall. Reinforced concrete walls represent the gold standard, requiring a minimum thickness of 200mm for residential applications. These walls must incorporate substantial steel reinforcement, typically consisting of horizontal steel beams or plates that extend well beyond the stair attachment points.

For brick or block construction, additional reinforcement becomes critical. Steel frame structures may be embedded within the wall cavity during construction, or existing walls may require significant modification to accommodate the cantilever loads. The wall must be designed to handle concentrated loads at each tread attachment point while distributing these forces safely to the building’s foundation.

Foundation reinforcement often extends below the supporting wall to handle the additional loads and overturning moments created by the cantilevered structure. In retrofit situations, this may require underpinning or foundation modifications to ensure adequate load capacity.

Building code compliance requires structural engineering certification and typically involves multiple inspection points during construction. The wall system must meet specific safety factors, typically requiring the ability to support loads several times greater than the expected service loads.

Types of Cantilevered Stair Systems

The world of floating staircases encompasses several distinct structural approaches, each offering unique benefits and aesthetic possibilities. Hidden stringer systems represent the most popular choice for residential applications, where steel support structures remain completely concealed within the wall. These systems create the purest floating effect, with treads appearing to emerge directly from the wall surface.

Exposed wall-mounted systems take a different approach, featuring visible laser-cut steel plates or brackets that support each tread. While these systems sacrifice some of the floating illusion, they often cost less than fully concealed systems and can create striking industrial or contemporary aesthetics. The visible supports become design elements themselves, often finished in powder-coated steel or other architectural metals.

Glass-supported cantilever stairs represent the cutting edge of floating staircase design. These systems incorporate structural glazing panels that provide transparent support while maintaining the open, airy feel. The engineering challenges are significant, requiring specialized structural glass and precise installation, but the visual impact is unmatched.

Hybrid systems combine multiple support methods, perhaps using hidden stringers for primary support while incorporating glass panels or cable systems for additional stability and safety. These approaches allow designers to balance structural requirements with aesthetic goals while potentially reducing costs.

Central Spine vs. Wall-Mounted Designs

Central spine systems, also known as mono-stringer designs, create freestanding cantilevered staircases that don’t require wall support. These systems utilize a single, heavy-duty steel beam running up the center of the staircase, with treads cantilevering from both sides. While technically challenging, these installations can create dramatic sculptural elements in large, open spaces.

Wall-mounted cantilever systems, by contrast, anchor directly to reinforced walls and represent the most common approach for residential applications. These systems maximize space efficiency by eliminating the need for central supports while creating the classic floating effect. The structural requirements are more predictable, and installation complexity is generally lower than central spine systems.

The choice between these approaches often comes down to available space, structural constraints, and aesthetic preferences. Wall-mounted systems work well in smaller spaces and integrate naturally with existing architecture, while central spine designs make bold statements in grand foyers or commercial spaces.

Installation complexity varies significantly between these approaches. Wall-mounted systems require substantial wall reinforcement but follow established engineering principles. Central spine systems demand more complex foundation work and precise structural calculations but offer greater flexibility in placement and orientation.

Materials for Cantilevered Stair Treads

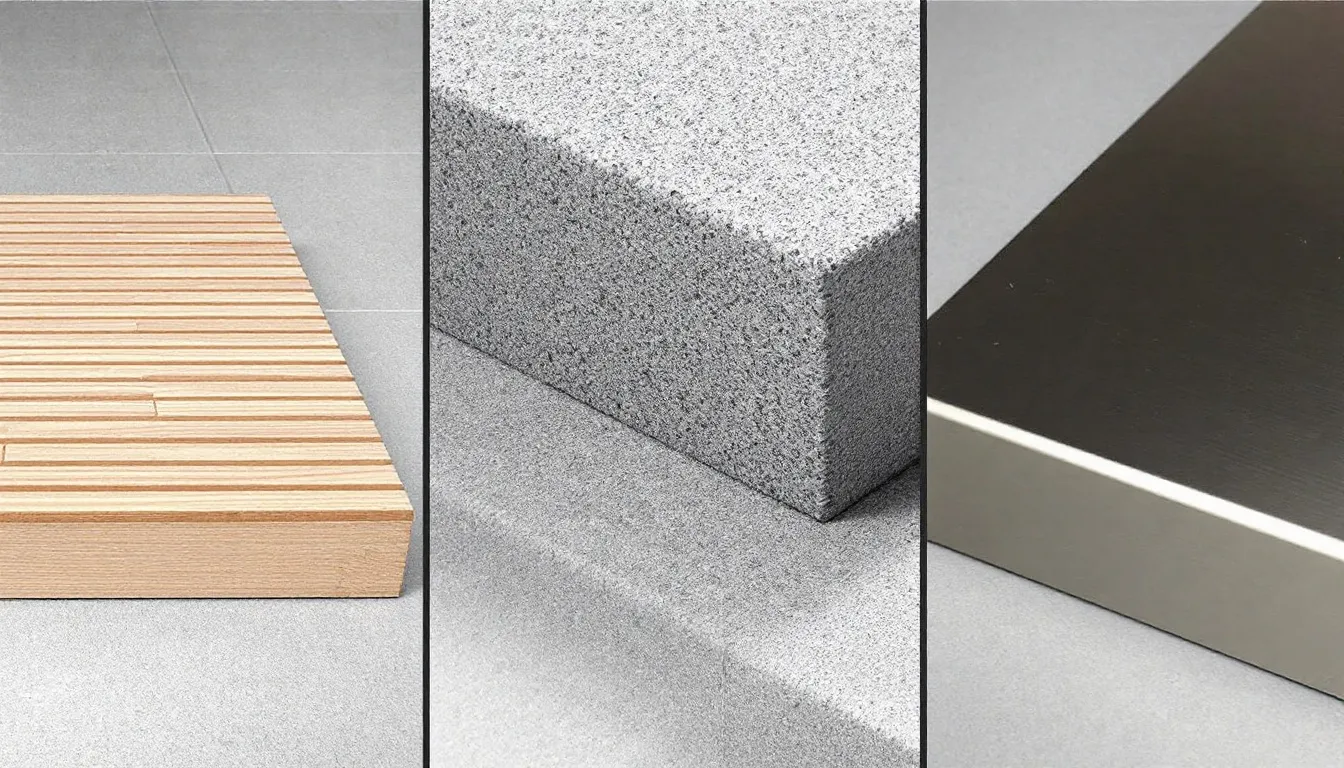

The choice of materials for cantilevered steps significantly impacts both the structural requirements and aesthetic outcome of your floating staircase. Hardwood remains the most popular choice for residential applications, with oak, walnut, and beech leading the selection. These materials typically require thickness ranging from 60-130mm, depending on the span and wood species. Oak treads weighing approximately 25kg each provide excellent strength-to-weight ratios while offering timeless aesthetic appeal.

Engineered materials like reinforced concrete treads offer exceptional durability and design flexibility. Concrete treads typically measure 80-110mm thick and can weigh up to 150kg each, requiring more robust structural support but delivering unmatched longevity. The weight difference between materials significantly affects the supporting wall requirements and overall project complexity.

Modern synthetic materials have opened new possibilities for cantilever stair design. Corian and other resin composites allow for seamless integration with contemporary interiors while offering excellent durability and minimal maintenance requirements. These materials can be formed into custom shapes and incorporate integrated lighting or other design features.

Steel and aluminum treads suit industrial or ultra-modern aesthetics while providing exceptional strength. These materials allow for very slim profiles—sometimes as thin as 40mm—creating the most dramatic floating effect possible. The precision manufacturing capabilities for metal treads also enable complex geometries and integrated safety features.

Tread Dimensions and Specifications

Standard residential cantilever stair treads typically measure 800-1200mm in width, though custom installations can extend up to 1500mm. Thickness requirements vary by material, with hardwood treads generally requiring 60-80mm minimum thickness for spans up to 1200mm. Engineered materials like concrete or steel can achieve similar spans with reduced thickness, sometimes as little as 40-50mm.

The weight considerations for different materials create cascading effects throughout the project. Timber treads at 25kg each place minimal demands on the support structure, while concrete treads at 150kg require substantially more robust anchoring systems. This weight difference can significantly impact project costs and complexity.

Commercial applications often require wider treads—up to 1500mm—to accommodate higher traffic volumes and accessibility requirements. These installations typically specify minimum thickness of 100mm regardless of material choice, prioritizing durability and safety over the slimmest possible profile.

Surface finishing options play crucial roles in both safety and aesthetics. Slip-resistant treatments, integrated LED lighting channels, and custom edge profiles all affect the final tread specifications. Modern manufacturing techniques allow for precise customization while maintaining structural integrity.

Installation Process and Timeline

The installation of cantilevered staircases requires careful coordination between structural engineers, fabricators, and installation specialists. Pre-construction planning begins with detailed structural engineering and permit acquisition, typically requiring 2-4 weeks for residential projects. Building permits for cantilever stairs often require additional documentation and structural calculations compared to conventional staircase installations.

Steel framework installation occurs during the rough construction phase, before walls are finished. This timing is critical—the support structure must be properly positioned and anchored before the wall construction is completed. The framework installation typically requires 1-2 days but must cure for several days before load testing.

Wall finishing and concealment of support structures represent the most delicate phase of construction. The wall surface must be completed to hide all traces of the structural system while maintaining access for final tread installation. This process requires coordination between framers, drywall contractors, and stair installers.

Final tread and railing installation typically requires 3-5 days for a standard residential staircase, though complex custom installations may require additional time. Each tread must be precisely positioned and secured, with final adjustments made to ensure perfect alignment and stability. The installation team tests each connection point and verifies the overall structural integrity before final approval.

Professional Requirements

Structural engineer certification is mandatory for cantilever stair projects, ensuring that all load calculations meet local building codes and safety requirements. The engineering fees typically range from $2,000-5,000 for residential projects, though complex installations may require additional analysis and documentation.

Specialized cantilever stair fabricators bring essential expertise to these projects. Unlike conventional stair builders, these professionals understand the unique requirements of floating staircase construction and possess the precision manufacturing capabilities necessary for successful installation. Their experience with material selection, connection details, and installation sequences proves invaluable.

Building inspection requirements involve multiple stages, typically including foundation inspection, rough framing inspection, and final structural inspection. Each phase must be approved before proceeding to the next construction stage. Some jurisdictions require load testing of the completed installation before final approval.

The collaboration between architects, engineers, and contractors becomes particularly important for cantilever stair projects. Early coordination ensures that structural requirements are integrated into the building design rather than retrofitted later. This integrated approach typically results in better outcomes and more efficient construction.

Design Considerations and Aesthetics

Cantilevered stairs excel at integrating with modern minimalist interior design principles, where clean lines and uncluttered spaces take precedence. The absence of visible support structures allows these floating staircases to enhance rather than dominate their surroundings. The minimalist style achieved through cantilever design creates visual continuity that enhances the overall architectural composition.

Lighting options for floating stairs offer unique opportunities to enhance their dramatic impact. LED strip lighting installed under each tread creates a gentle glow that emphasizes the floating effect while providing functional illumination. Wall-washing effects from hidden fixtures can create stunning shadow patterns that change throughout the day as natural light shifts.

Railing systems for cantilevered staircases must balance safety requirements with aesthetic goals. Glass panels maintain the open, transparent feeling while meeting building code requirements. Cable railing systems offer minimal visual impact while providing necessary safety barriers. Minimalist steel designs can complement industrial or contemporary interiors while maintaining the clean lines that make cantilever stairs so appealing.

The open riser design typical of floating staircases maximizes light penetration through the structure. This transparency allows natural light to reach areas that would otherwise be shadowed by conventional stair construction. The result is brighter, more inviting spaces that feel larger and more connected.

Space Planning Benefits

Cantilevered staircases deliver significant space utilization advantages compared to traditional staircase construction. The absence of understair supports creates usable floor space that would otherwise be occupied by structural elements. This recovered space can accommodate furniture, storage, or simply remain open to enhance the sense of spaciousness.

Enhanced natural light flow represents one of the most valuable benefits of floating stair design. Traditional staircases with solid risers and substantial stringers block light transmission between floors. Cantilever stairs allow light to flow freely through the structure, brightening adjacent spaces and reducing the need for artificial lighting during daylight hours.

The visual expansion of room dimensions achieved through cantilever design can make spaces appear significantly larger than their actual square footage. The transparency and lightness of floating stairs avoid the visual weight of conventional construction, creating an airy feel that enhances the perception of space.

Integration with open-plan architectural concepts makes cantilever stairs natural choices for contemporary homes. These structures support the flowing, connected spaces that define modern living while providing essential vertical circulation. The stairs become part of the open plan rather than barriers within it.

Cost Factors and Budget Planning

Understanding the financial investment required for cantilevered stairs helps ensure realistic project planning and budgeting. Timber-based floating staircase systems typically range from $8,000-15,000 for residential installations, including materials and professional installation. These systems offer excellent value for homeowners seeking the cantilever aesthetic without the highest-end price points.

Concrete and steel cantilever systems command higher prices, typically ranging from $15,000-30,000 for comparable residential installations. The increased cost reflects the more complex engineering requirements, specialized fabrication, and heavier structural demands. However, these systems often provide superior long-term durability and can support more ambitious design concepts.

Structural engineering fees represent a significant component of project costs, typically accounting for $2,000-5,000 of the total budget for residential projects. This investment ensures proper load calculations, building code compliance, and safe installation. Complex designs or retrofit installations may require additional engineering analysis, increasing these costs.

Installation complexity significantly affects labor costs, often representing 20-40% of the total project cost. The specialized skills required for cantilever stair installation, combined with the precision necessary for proper execution, justify these higher labor rates. Experienced installers can complete projects more efficiently while ensuring proper structural performance.

Long-term maintenance considerations should factor into budget planning. While cantilever stairs generally require minimal maintenance, periodic inspections of structural connections and tread conditions ensure continued safety. Replacement costs for individual treads or structural components can be significant, making initial quality investment worthwhile.

Safety Standards and Building Codes

International Building Code (IBC) requirements specifically address cantilever stair construction, establishing minimum safety standards for structural capacity, dimensional requirements, and installation practices. These codes ensure that floating staircases provide the same level of safety as conventional stair construction while accommodating their unique structural characteristics.

Handrail height specifications require careful attention, with residential applications typically requiring rails between 34-38 inches high. The open design of cantilever stairs makes proper railing installation critical for user safety. Building codes may specify additional requirements for glass railings or cable systems to ensure adequate safety barriers.

Load testing requirements mandate that cantilever stairs support minimum live loads of 40 pounds per square foot for residential applications. Commercial installations may require higher load capacities and more rigorous testing protocols. These requirements ensure that the stairs can safely support normal use loads with appropriate safety margins.

Fire safety considerations and egress requirements apply to cantilever stairs just as they do to conventional staircase construction. The open design of floating stairs generally enhances egress visibility and smoke clearance, though specific local requirements may impose additional constraints on materials or construction methods.

Regular inspection and maintenance schedules help ensure continued compliance with safety standards. Professional inspection of structural connections, tread conditions, and railing integrity should occur periodically, particularly in high-traffic installations. Proper documentation of these inspections helps maintain insurance coverage and regulatory compliance.

Conclusion

Cantilevered stairs represent the perfect fusion of engineering innovation and architectural artistry, creating stunning focal points that enhance modern living spaces. From their hidden steel support systems to their variety of material options, these floating staircases offer unmatched design flexibility while delivering practical benefits like improved space utilization and natural light flow.

The investment in a cantilever stair system extends beyond the initial construction costs—these structures add elegance and contemporary appeal that can significantly enhance property values. Whether you’re planning new construction or considering a renovation project, the dramatic impact of floating stairs makes them worthy of serious consideration.

Success with cantilever stair projects requires careful planning, professional engineering, and experienced installation teams. The structural requirements and safety considerations demand expertise that only qualified professionals can provide. By understanding the engineering principles, material options, and cost factors outlined in this guide, you’re better equipped to make informed decisions about incorporating these remarkable structures into your architectural vision.

The future of staircase design continues to evolve, but cantilevered stairs have established themselves as timeless expressions of modern architecture. Their ability to create airy, light-filled spaces while providing essential vertical circulation ensures their continued popularity in contemporary design. If you’re ready to elevate your space with the striking beauty of floating stairs, start by consulting with qualified structural engineers and experienced cantilever stair specialists who can bring your vision to life safely and successfully.