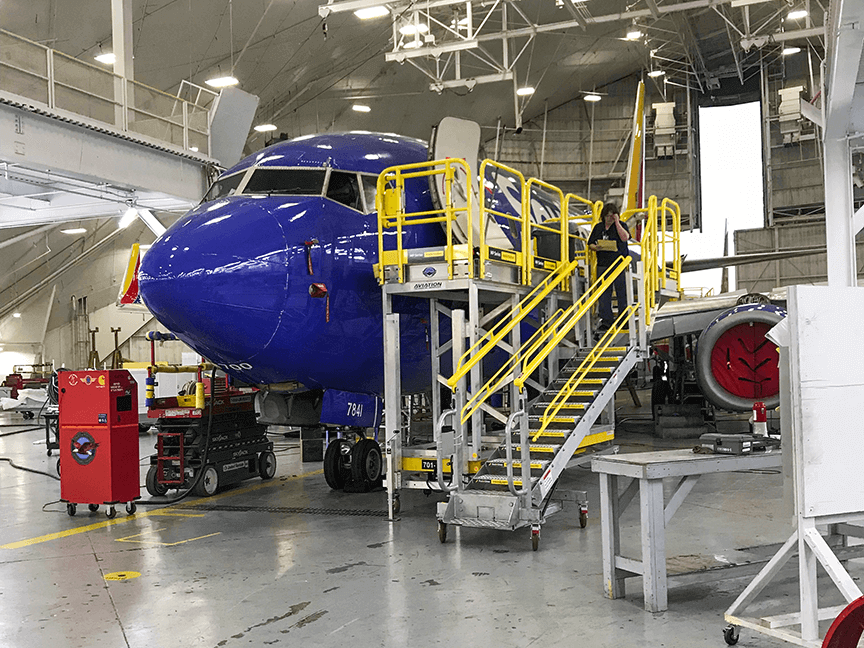

A manufacturing company in Nebraska asked ErectaStep for a modular, easy to assemble, and custom solution to replace an outside wooden stairway that was quickly falling into disrepair on the company’s roof. The steep and unsafe stairway located on the roof reached great heights to another section of the roof. The current wood staircase was beginning to rot and wooden stair treads were getting slippery, especially when wet or when snow was present. ErectaStep came up with a solution to fit their needs and of course, the stairs are OSHA compliant. They agreed on a stair system with steel support pedestals to reach the height of 18’. This stair system was made with lightweight, aluminum components to make the process of getting the piece onto the roof for installation easier, as well as, reducing the weight of the system sitting on the roof. The PefectaStep team also used an intricate tread pattern to prevent slippery conditions, even when it was raining or snowing. Safety is a top concern so ErectaStep made sure the stairway solution would give them a safe and reliable solution that would last for decades over a wooden made system.

When assembling the ErectaStep system the employees were quick to comment about how fast the process was going compared to a large amount of time it took to build the wooden system years ago. Relief could be seen on their faces as they had been facing dangerous conditions daily. Once the project was complete the customer expressed their joy for having a safe, OSHA compliant system in place that will require much less maintenance and no foreseeable timeline for replacement.