What Is Mill Finish?

Mill finish is a term used to describe the natural surface condition of metal as it comes from the mill, meaning it has not been treated, coated, or polished after the manufacturing process. This finish is common on aluminum and steel products.

What Does Mill Finish Look Like?

Mill finish metals typically have a slightly matte or shiny appearance, with subtle lines or marks from the rolling or extrusion process. Unlike painted or powder-coated surfaces, mill finish does not have added color, gloss, or texture. The result is a raw, industrial look that showcases the natural characteristics of the metal.

How Is Mill Finish Produced?

When metals like aluminum or steel are formed into sheets, bars, or extrusions at the mill, they pass through rollers or dies. The surfaces are left as-is, without any secondary finishing steps such as sanding, polishing, anodizing, or painting. This is what’s referred to as “mill finish.”

Advantages of Mill Finish

- Cost-Effective: Because no additional finishing steps are required, mill finish is often the most economical option.

- Fast Lead Times: Mill finish products are typically in stock and ready to ship, reducing project timelines.

- Natural Appearance: The raw, metallic look is ideal for industrial settings or projects where a modern, utilitarian aesthetic is desired.

- Durability: For aluminum products, mill finish provides a corrosion-resistant surface that will not rust, making it suitable for both indoor and outdoor use.

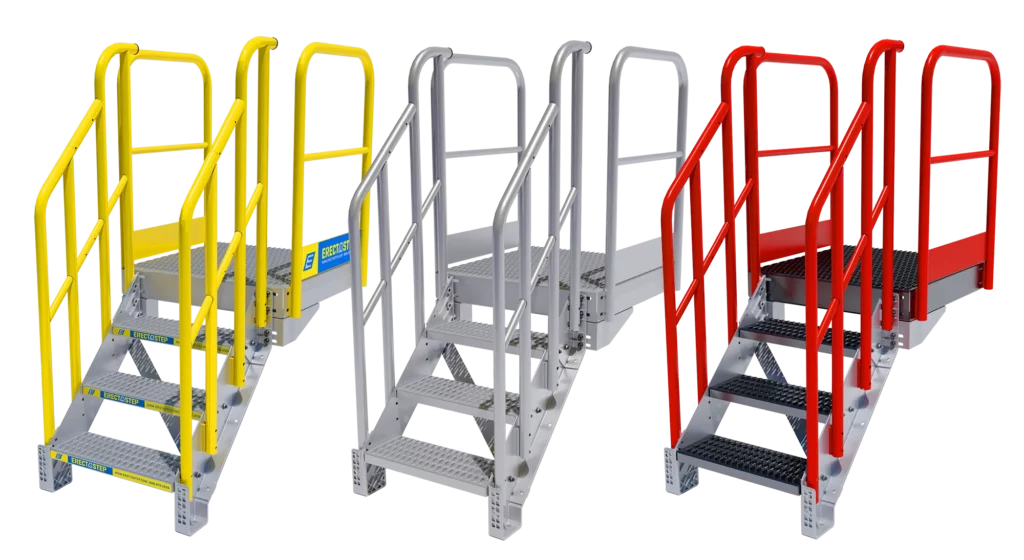

Mill Finish and ErectaStep Stairs, Handrails & YellowGate Safety Gates

At ErectaStep, our standard stairs, towers, and platform handrails are typically powder-coated in OSHA safety yellow for maximum visibility and compliance, but they can also be supplied in mill-finish aluminum. Customers can choose mill-finish handrails for applications where aesthetics are important, such as publicly visible installations or architectural projects.

Mill finish aluminum is especially popular in the following scenarios:

- Architectural or Public Spaces: Where a clean, metallic look is preferred over bright safety colors.

- Fast-Track Projects: When quick delivery is essential, as mill finish components are in stock and ready to assemble.

- Low Maintenance Needs: Mill finish aluminum will not rust, warp, or require repainting, making it a smart choice for harsh or outdoor environments.

ErectaStep Customization Options

While mill finish is the standard for most ErectaStep structural components, we also offer custom finishes-including powder coating in a variety of colors-to meet specific safety, branding, or architectural requirements.