Ensuring Safety and Efficiency in Boeing’s CST-100 Starliner Assembly for NASA’s Commercial Crew Program

We’re proud to be a part of making NASA’s Commercial Crew Program possible. This initiative aims to return human spaceflight launches to American soil. To make this goal a reality, NASA asked private companies to develop human spaceflight systems—exactly what Boeing did.

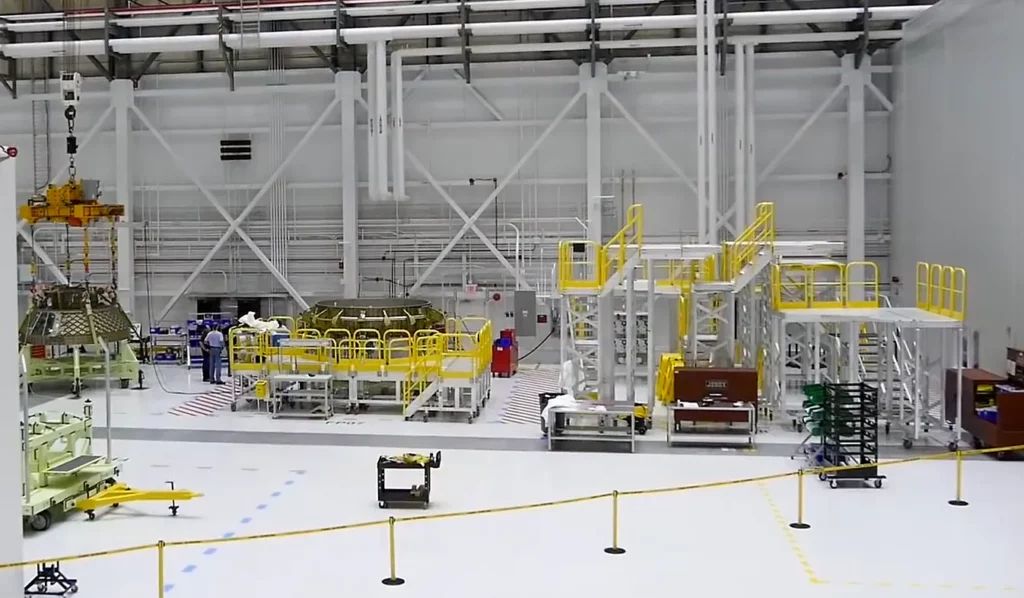

Boeing’s CST-100 Starliner is the most advanced space capsule ever built. It can fit up to seven passengers on its intended journey to the International Space Station. The first crewed missions to the ISS are expected in late 2018. Because the Starliner can land on solid ground, it is reusable up to 10 times. The first capsule has already been completed and is currently undergoing multiple tests, while the second capsule is in production at Kennedy Space Center.

Safe Space

Combined, the CST-100 Starliner team has more than a century of experience in human space missions. Every step in the manufacturing process was carefully analyzed for precision and held to the strictest standards. Even solutions that allowed workers access to difficult-to-reach parts and the ability to cross over job site obstacles had to be intelligently incorporated into the complex workspace. ErectaStep’s solutions were the only product that met the stringent standards set by NASA and Boeing.

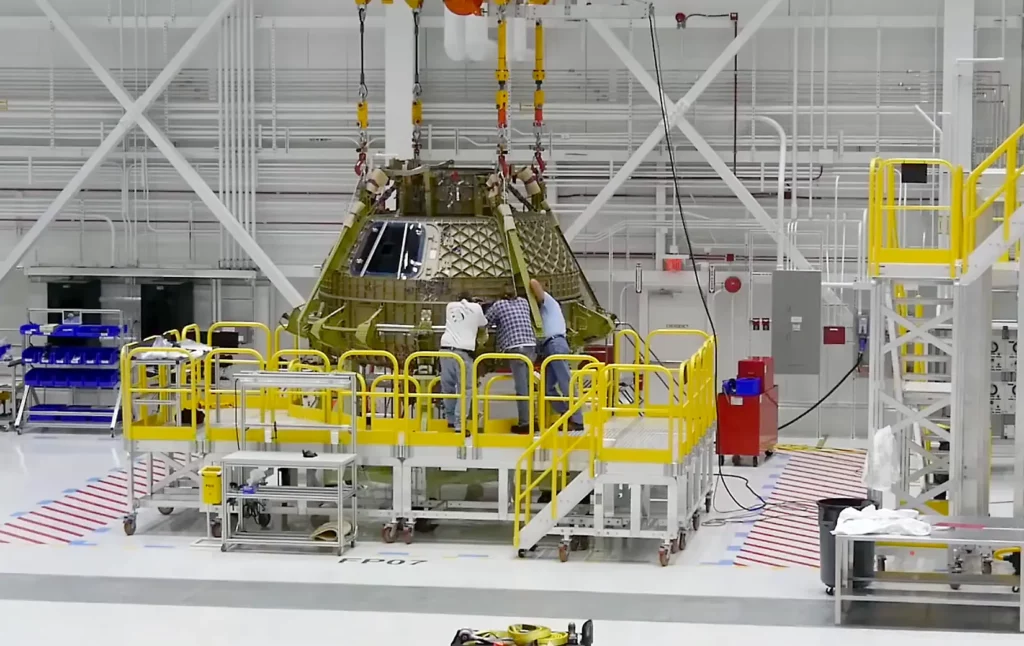

Our mobile platform is being used to access the Starliner’s upper dome, lower dome, and docking hatch and outfit each component with wiring harnesses, avionics, and other systems. These parts are handled separately, and then, after substantial testing, they are joined together to form a complete CST-100 capsule. The Starliner team needed strong, reliable, and safe crossover systems and work platforms to ensure these components were built perfectly each and every time.

RollaStep MP Series is anything but a standard mobile work platform

The RollaStep MP Series is a highly customizable mobile work platform designed to bring the workspace and stability of a fixed platform to a rolling stair mobile unit.his installation is an example of how RollaStep can be adapted to complicated and mission-critical projects.

The CST-100 Starliner’s Chief Mechanic, Barry Decker, is involved in building the capsule. He is always quick to explain the importance of safety in his workplace because astronauts’ lives are at stake. “What they’re doing up there is good for mankind, and my job is to make sure they get home for dinner – that’s all that I care about. It has to be safe,” says Decker. Whether you’re going to space or simply accessing a tanker trunk here on Earth, we can help you keep safe every step of the way.

Contact an ErectaStep representative today to learn how our customizable solutions can solve your workplace safety problem.