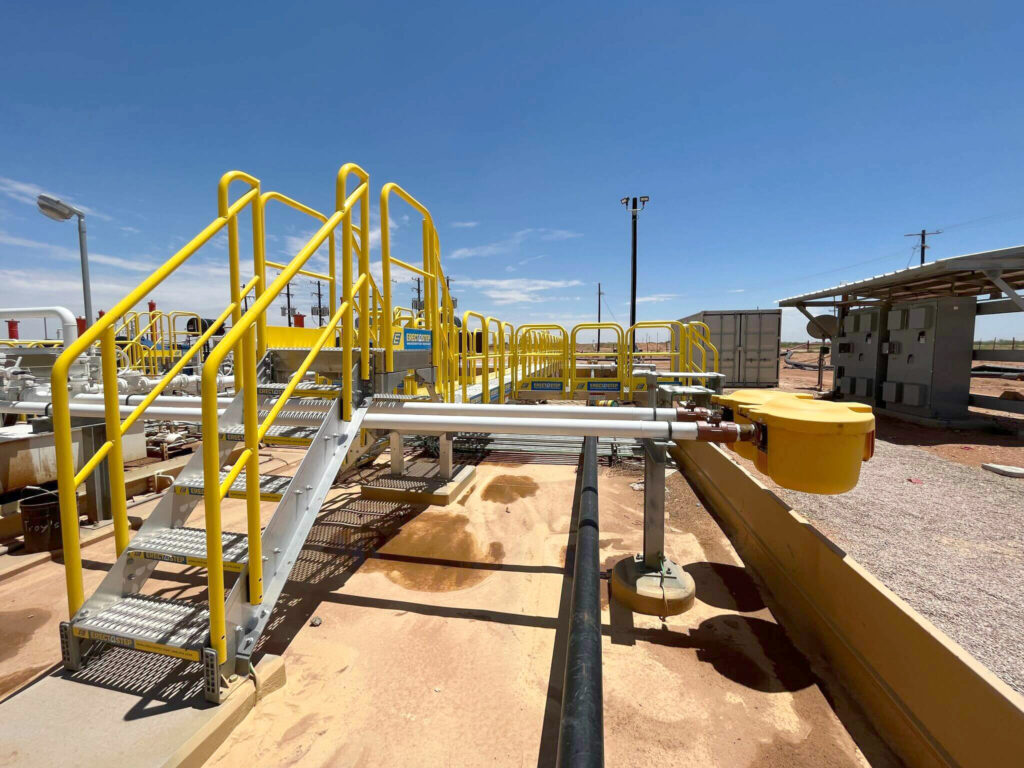

Proven Across Industries, ErectaStep catwalk installations are operating in oil and gas facilities, refineries, tank farms, food and beverage plants, wineries, power generation sites, water treatment centers, warehouses, and infrastructure projects across the U.S., Canada, and internationally. Each installation is delivered through ErectaStep’s distributor network with technical support from regional product experts who stay engaged from initial site visit through final installation.

What Is an Industrial Catwalk?

An industrial catwalk is a narrow, elevated pathway or extended platform that provides safe access to elevated work zones. Also referred to as runways, catwalks enable workers to reach equipment, maintenance areas, piping, valves, and other locations within a facility that would otherwise require ladders, scaffolding, or temporary structures.

Catwalks are distinct from standard platforms in that they typically span longer distances, bridge obstacles, and connect multiple access points across a facility. They serve as both a walkway and a work surface, depending on the configuration.

Common Catwalk Applications

Catwalk configurations vary widely depending on the facility and the access problem being solved. Below are the most common applications where catwalks deliver measurable operational value.

Pipe and Valve Access

In petrochemical plants, refineries, and tank farms, catwalks provide workers with safe, repeatable access to valves, gauges, and instrumentation mounted on or near piping runs. A recent installation in Canada used an ErectaStep modular crossover configured as a catwalk to bridge an LP steam vent line and give maintenance crews access to multiple valves. This eliminates the need for ladders or scaffolding every time a valve requires service.

Rooftop Crossovers and HVAC Access

Rooftop environments present unique challenges: pipes, ductwork, and mechanical equipment often obstruct direct walking paths. ErectaStep catwalk configurations have been installed to navigate narrow roof sections interspersed with pipes, using off-the-shelf modular components with no custom fabrication. These installations give maintenance personnel safe passage to HVAC units, exhaust fans, and rooftop equipment.

Tank Farm and Process Equipment Access

Catwalks configured to span between tanks or run alongside process vessels give operators consistent access to hatches, sight glasses, and control instruments. ErectaStep has delivered catwalk solutions for cosmetic manufacturers needing access to compounding and holding tanks, as well as shell technology centers requiring access to controls mounted on top of tanks.

Conveyor Crossovers

In manufacturing, food processing, and distribution facilities, conveyors create physical barriers on the floor. Catwalk crossovers allow workers to pass safely over conveyor lines while maintaining OSHA-compliant fall protection throughout.

Bridge and Infrastructure Maintenance

Catwalks are used on bridges and infrastructure for inspection and maintenance access. ErectaStep delivered a catwalk installation for the Roosevelt Bridge in New York, demonstrating how modular components adapt to non-standard structural environments.

Winery and Food/Beverage Production

Smaller production facilities benefit from catwalk access as well. At Saint Paul Mountain Vineyards, a 45-foot ErectaStep catwalk system was installed in a single day, giving staff safe access to wine vats. The owner noted the speed of installation and the ability to reconfigure the system as production grows.

Why Modular Catwalks Outperform Custom Fabrication

ErectaStep’s five standardized, bolt-together components—stairs, platforms, handrails, ladders, and tower supports—can be configured into virtually any catwalk layout. This modular approach addresses the problems that operations, maintenance, and safety professionals deal with regularly:

- No welding, hot permits, or production shutdowns. Components bolt together with standard tools. A Sarasota, FL facility installed a full catwalk system without disrupting operations.

- Fast deployment. Standard components are in stock and ready to ship. Most configurations are assembled and installed within days.

- Reconfigurable. When equipment moves or processes change, the catwalk can be unbolted and reinstalled in a new configuration. This is particularly valuable in facilities that undergo frequent layout changes.

- OSHA-compliant by design. Every component is pre-engineered to meet OSHA 1910.25 standards for tread depth, riser height, handrail specifications, and load capacity.

- Corrosion-resistant aluminum construction. Lightweight, maintenance-free, and suitable for indoor, outdoor, and corrosive environments. Galvanized, stainless steel, and steel options are also available.

OSHA Compliance Requirements

Any catwalk installed in a general industry setting must meet OSHA 29 CFR 1910 Subpart D standards for walking-working surfaces. Key requirements include:

- Minimum catwalk width of 18 inches; 22 inches minimum if accessed by a stairway; 36 inches minimum if accessed by IBC stairs.

- Guardrails required for catwalks higher than 4 feet above a lower level, capable of withstanding at least 200 pounds of force.

- Toeboards with a minimum vertical height of 3.5 inches to prevent objects from falling off elevated walkways.

- Non-slip walking surfaces and regular inspection and maintenance of all walking-working surfaces.

- Stair access with a maximum riser height of 9.5 inches and minimum tread depth of 9.5 inches.

Configuring a Catwalk

ErectaStep uses a proprietary configurator tool that produces shop drawings and realistic renderings in minutes. Three platforms can be bolted together without tower supports, providing up to 9 feet of linear clearance. For longer spans, tower supports are added at the 9-foot mark and at each end, extending the catwalk to the required length.

Custom components can be integrated with standard modular pieces for challenging installations—contoured platforms, custom openings, and non-standard widths are all available. An authorized distributor, supported by ErectaStep’s product experts, handles site assessment, configuration, delivery, and installation.