Introducing the Counterweight-Based Stair & Crossover Solutions

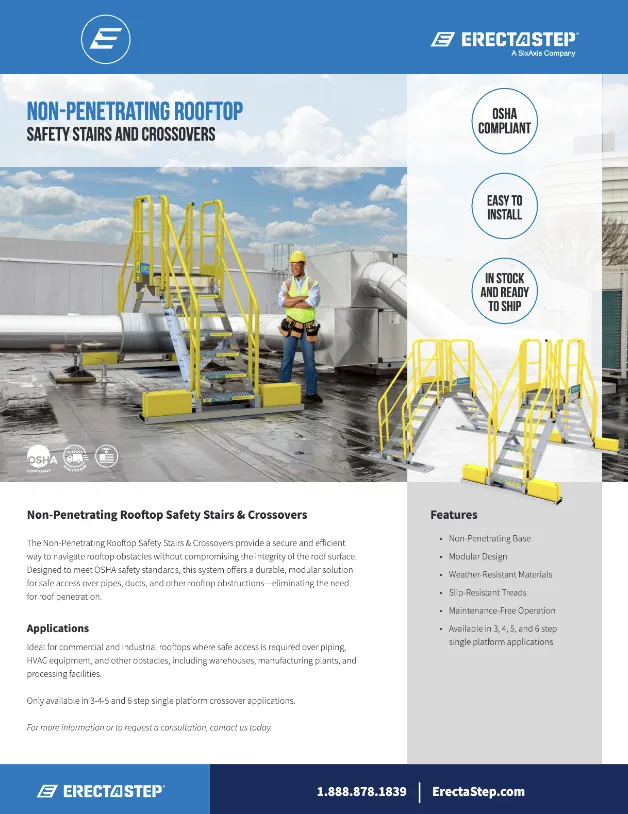

Accessing rooftop equipment such as HVAC units, ductwork, or piping requires safe, compliant, and non-disruptive infrastructure. ErectaStep’s counterweight-based rooftop stair and crossover system provides a secure, non-penetrating access solution that protects roof integrity while ensuring worker safety.

Ideal for Applications Such as:

Commercial

Rooftops

With no existing anchor points.

Manufacturing and Processing Plants

Requiring maintenance access to rooftop utilities.

Warehouses and Distribution Centers

Needing compliant crossover systems that protect roofing warranties.

System Overview and Key Design Elements

This rooftop solution integrates ErectaStep’s modular aluminum platforms and stair assemblies with a galvanized steel base equipped with integrated counterweight trays. The trays hold powder-coated steel weights and neoprene load-distribution strips, which stabilize the structure while preserving the roofing surface.

- Non-Penetrating Support: Eliminates the need for drilling or anchoring into the roof membrane, preventing damage and reducing installation time.

- Counterweighted Stability: Powder-coated steel weights and a widened base ensure a stable footprint in wind conditions up to 115 mph, ideal for open or elevated rooftop environments.

- Durable & Weather-Resistant: Built from corrosion-resistant aluminum and galvanized steel for long-term performance in harsh climates.

- Slip-Resistant and OSHA-Compliant: All treads and platform surfaces meet OSHA standards for fall protection and traction, minimizing safety risks.

- Standard Configurations: Pre-engineered options in 3-, 4-, 5-, and 6-step crossover heights accommodate various rooftop obstructions and elevation changes.

Counterweight Performance Specifications

| Steps | Total System Weight | Wind Shear Load | Wind Overturning Moment |

|---|---|---|---|

| 3 | 1,690 lb | 1,202 lb | 2,236 lb-ft |

| 4 | 1,828 lb | 1,432 lb | 3,226 lb-ft |

| 5 | 2,146 lb | 1,660 lb | 4,386 lb-ft |

| 6 | 2,454 lb | 1,889 lb | 5,716 lb-ft |

- Static Load Capacity: 50 PSF on platforms and 1,000 lb on stairs.

- Max Roof Height: 50 ft

- Wind Rating: 115 mph

Customers are responsible for verifying roof load capacity and suitability for friction-based support systems.

FAQs

No, the counterweight base is designed specifically for flat rooftop applications.

Yes. All ErectaStep components meet OSHA safety standards.

This configuration supports only single platform units with 3 to 6 steps.

Units are in stock and ready to ship. Installation is fast and requires no special tools or roof penetrations.

Counterweight vs. Tie-Down Systems

ErectaStep offers two distinct rooftop mounting solutions to meet varied structural and regulatory requirements: the counterweight-based system and the tie-down anchored system. Each method serves a specific application need, and understanding the differences can help facility managers and contractors choose the best option for their site conditions.

The counterweight system is a fully self-supporting solution that does not require any physical attachment to the roof. It relies on integrated galvanized trays loaded with powder-coated steel weights to provide mass and stability. This design is ideal for facilities with sensitive roofing materials, such as membrane or green roofs, where drilling or penetration could lead to leaks, warranty issues, or costly damage. Installation is faster and less invasive since it does not require structural anchoring, and the use of neoprene strips beneath the trays distributes weight evenly to prevent surface abrasion or deformation. Engineered to withstand wind speeds of up to 115 mph, this system provides secure and code-compliant access without permanent roof alterations.

In contrast, the tie-down system uses mechanical fasteners and rooftop shackles to anchor the stair and platform assemblies directly to the building structure. This approach may be preferred in locations where permanent anchoring is permitted or where existing tie-down infrastructure is already present. While this method can offer slightly higher rigidity in extreme conditions, it involves roof penetration, which may necessitate special permits, additional weatherproofing, and ongoing inspection to ensure long-term watertightness.

Choosing between these two mounting systems depends on site-specific variables such as roofing material, local building codes, exposure to wind loads, and installation constraints. The counterweight option provides greater flexibility and ease of deployment, particularly in retrofit or leased facilities, while the tie-down method is suitable for permanent installations where roof penetration is allowed.